Virtual testing with virtual humans is possible thanks to artificial intelligence and digital twins.

Hexagon has submitted this post. Written by Aditya Vipradas, Business Development Manager (Machine Learning Solutions).

In today’s virtual-for-everything research and development world, it is no surprise there is an initiative that focuses on the virtual human. The virtual human has many practical applications such as the study and prevention of trauma or the improvement of diagnosis and surgical techniques. With multi-scale analysis, tissues, limbs, body sections, or complete human models can be used for virtual testing.

The Laboratory of Biomechanics and Application (LBA) is a joint research unit between the Université Gustave Eiffel’s transport, health, safety department and the Aix-Marseille Faculty of Medicine. LBA is located on the premises of the Faculty of Medicine in the northern Marseille Health Center in France. The multi-disciplinary approach in this laboratory combines both engineering and medical science expertise to focus on human impact biomechanics. Supported by 39 collaborating research staff, the LBA is designing tools and human models for virtual testing to achieve their own vision of a “Virtual Human.” Their practical research has taken root in the real world affecting clinical and surgical settings, as well as transportation safety.

An Orthopedic Challenge

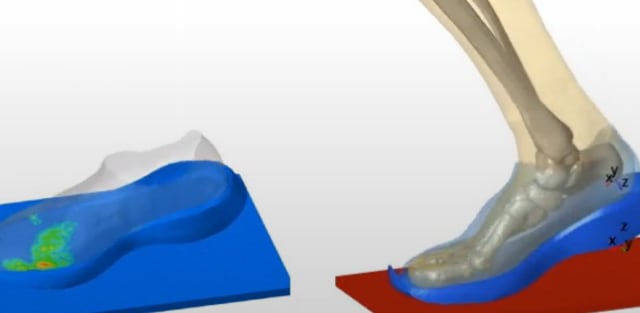

The virtual human and limb models created by LBA have practical applications for injury prevention analysis and clinical settings. A developed foot-limb model is currently being used for emerging medical applications such as optimizing orthopedic insoles that can be easily 3D printed right in the clinic. Researchers utilize up to seven different engineering software programs to comprehensively model the dynamics of a realistic walking gait. A digital twin model of the patient’s foot can be leveraged to gain insights on how to improve insoles for a patient’s specific needs. The adjusted custom insole can maximize the intended effect of the insole and the comfort of the patient.

The current foot model requires significant time to accurately render the effects of the insole. LBA used a CAE-centric platform, ODYSSEE CAE from Hexagon’s Manufacturing Intelligence division, to leverage the model and provide easy-to-understand, instantaneous feedback as needed by clinical podiatrists. This platform allows users to apply machine learning, artificial intelligence, reduced order modeling and design optimization to workflows and create cost effective digital twins based on CAE simulation data and physical test data. Complex engineering questions can be answered in real-time that would ordinarily take hundreds of hours to simulate and analyze.

Walking Toward the Solution

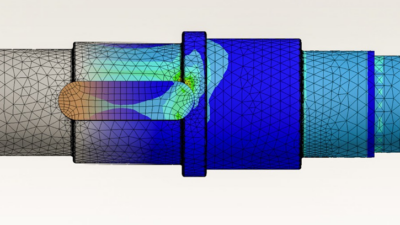

The LBA’s foot model provides a complete examination of the patient’s walking gait. The analysis of the walking dynamics was conducted by dividing the gait into four phases, then accounting for details caused by the different properties of bone, soft plantar tissue, skin tissue, ligaments, joint placement, joint stiffness, and the ground. The parameters of the foot and insole models were modified according to the measurements of the patient’s foot. This adjustment creates the numerical (digital) twin of the actual patient, mimicking any kind of foot geometry, gait, and walking pattern.

Utilizing the same CAE software, LBA used thirty simulations of the original foot model to create a reduced order model that accommodates any foot geometry and accurately reproduces the dynamics of the patient’s walking gait. The sensitivity studies of the reduced model showed the parameters with the largest effect on the gait. The software was able to generate near instantaneous feedback using the reduced order model, increasing the usefulness of the model to clinicians.

Enhanced Care and Comfort Results

Real-time analysis feedback aids podiatrists in providing the best possible care to their patients. The resulting reduced foot model accurately predicts the dynamic response of the comprehensive model in less than one second compared to the four hours needed to resolve the full model. The predictions of the reduced model matched very closely the center of pressure displacement observed in the original model. The ability to digitally match different insole designs to the patient’s foot and observe the effects in real time allows for rapid optimization of the design to reach the intended effect.

Custom insoles can also be enhanced with differing materials, local densities, and geometries to best meet the patient’s needs. The reduced model has also shown promise in improving the outsoles of some sport shoes. Another major benefit of using digital twin foot models is the ease of 3D printing the custom insole. The practical application of LBA’s foot model has been accentuated through CAE real-time predictive analysis, and this approach has been successfully implemented in partnering podiatric clinics.

To learn more, visit Hexagon.com.