How simulation is accelerating healthcare innovation.

Siemens has submitted this post.

Written by: Stephen Ferguson, Director of Marketing, Siemens Digital Industries Software.

Ever wondered why the medical devices we see in sci-fi shows are taking so long to become a reality? Surely, with the rapid advancement of technology in the 21st century, we should be seeing more equipment that helps people live longer and healthier lives?

It’s not for want of trying. But the problem is that while the rewards (both humanitarian and financial) are high, so are the risks.

Large companies in the medical industry are successful because they adopt low-risk strategies that guarantee returns. So, the real innovation in medical technology is left to small entrepreneurial companies.

But according Embroker Insurance Services and Mark Carol of the Focused Ultrasound Foundation, at least 90 percent of these companies fail, and we never get to see their advanced devices on the market.

One of the major reasons for this is the amount of time – around 10 years – it takes to carry out all the necessary trials to ensure the safety of a new product.

But what if you could speed up that process?

Simulation is the Key to Speeding up Healthcare Development

We can learn a lot from in vivo testing on mice, but there comes a point where we need to go further. Traditional ex vivo, in vitro and in situ experiments require extensive regulatory approval as they all involve humans. Thus, extreme care must be taken not to cause harm to anyone.

This is what causes the delays that make it so difficult for small businesses to succeed.

Our need to do everything we can to protect human life is the very thing that holds us back from making advances that can protect and advance human life even further. It’s quite the Catch-22.

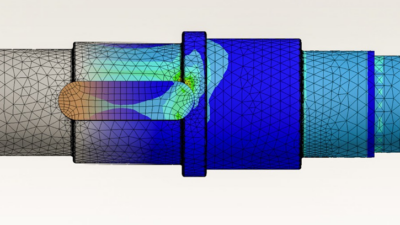

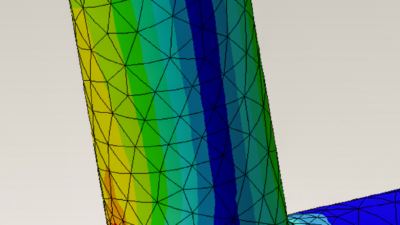

However, that is changing with the introduction of in silico trials which are carried out in virtual simulations. The beauty of this is there are no humans involved, and therefore no one can be harmed. And that means there is no requirement for the vast amount of regulation involved in other trials.

Failing Fast

Failing fast is critical to innovation in any form of engineering. You get it wrong, then you understand how it went wrong, and you build something better. But getting it wrong isn’t an option when you’re testing on humans. However, if all your testing is carried out in a simulation environment, you can get it wrong as many times as you like.

Tim Dieryckx is the CEO of Voxdale, a company that utilizes Siemens’ Simcenter to speed up their customers’ development process. He explains, “Simulation allows us to come up with quick results and fail fast. We truly believe we’re building fantastic hardware. It means failing fast and getting quick results. I think we learned a little bit from the people in software development, in hardware development. If you can do it in an in silico environment, instead of in a physical environment, it has a huge amount of added value.”

Better Optimization

The problem in the medical industry, Dieryckx says, is that once you have developed something and it works, you freeze the design and don’t progress it any further. There’s simply too much financial risk involved for the further trials that would be required to find an optimal solution.

Simcenter allows companies to optimize their products before spending too much time and money in laboratories. Voxdale use its teams’ expertise in electronics, robotics, fluid dynamics and thermal analysis to help the most advanced innovations. “We’re now working on a lot of microfluidics, lab-on-a-chip and organ-on-chip projects,” says Dieryckx. These are challenging for simulation technology, but he explains that it’s continually evolving with help from developers. The more obstacles thrown at it, the better simulation solutions are getting at overcoming them and pushing the boundaries of what’s possible.

Real-World Innovations

So, what innovations has in silico testing brought to market so far? Here are two examples that involved Voxdale.

Remember the sheer number of COVID-19 vaccines that needed to be created and distributed worldwide? Well, that wasn’t the first pandemic, and it certainly won’t the be the last. But the good news is that there’s a new automated vaccination device that will hopefully be ready well before we’re struck by such an infectious and dangerous disease again. Not only will this device reduce the amount of vaccine required per person, but it will also reduce the reliance on medical professionals to administer it. A tool like this would be essential when fast vaccine rollout is critical to mitigating a pandemic. Dieryckx explains that simulation enabled them to get from concept to the production of the first moulds “in just four months – which is unheard of.”

Another new device that automatically analyses urine samples has had its development time sped up thanks to in silico trials. It allows early detection of sexually transmitted infections such as HPV or chlamydia, and certain cancer biomarkers, including prostate cancer. Again, this can be a critical device when early detection and treatment leads to a hugely improved chance of a positive patient outcome.

“If we hadn’t been able to leverage the technology of simulation engineering, we would have been much more conservative,” says Dieryckx. “We’d have gone for solutions that we were completely sure would work. And I’m quite sure that would have hampered us a lot in the market because our cost of goods would be too high.”

Simcenter for a Healthier World

There are plenty more projects currently ongoing that are benefitting from in silico trials. Understandably, the details of most will remain strictly confidential until they are ready to be launched. But there can be no doubt that we’ll see many new medical devices come to market in the coming years that wouldn’t have been possible without the use of simulation.

And it’s not only through medical device development that Simcenter is helping to improve lives. It’s also being used in prosthetic engineering, personalised medicine and much more.

Want to know how digital twins will help us live longer, healthier, happier and more productive lives? Read all about it here.