There are three general phases to analyzing a 3D model: pre-processing, solving and post-processing.

Engineers often refer to a 3D model analysis as “running a simulation” or “conducting a simulation study.” Think of it as designing an experiment, which requires knowledge, resources and planning. In typical simulation studies, there are three general phases:

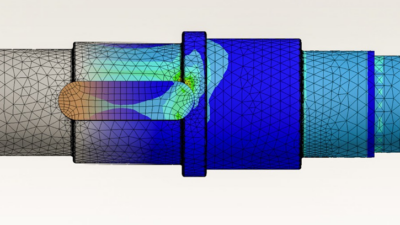

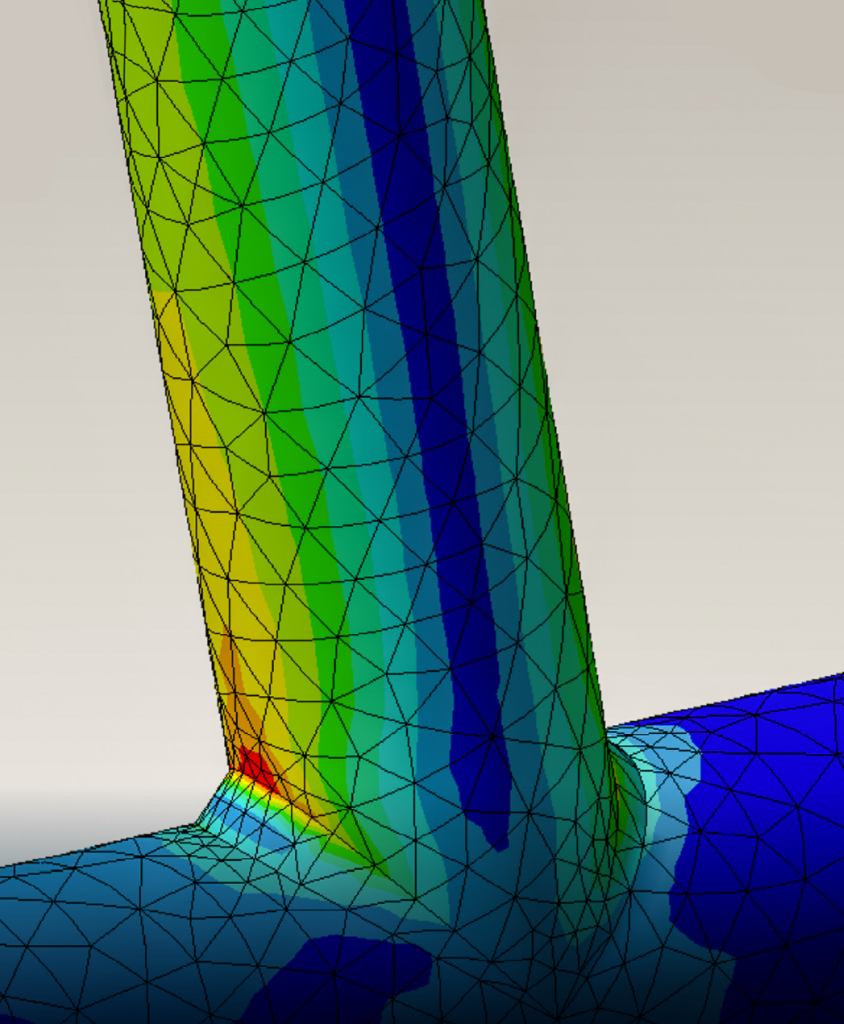

Pre-processing: This is the simulation setup and involves importing a CAD file, defining all properties of the 3D model, creating the mesh and applying constraints and conditions. This step is critical for a successful simulation study with accurate results. Some CAE software has built-in pre-processors with a graphical user interface (GUI) for easy importing and setup. Others without a pre-processor or GUI require engineers to create a data file in an exact format. There is also independent pre-processor software to make the entire pre-processing step, or parts of it, easier with exportable files.

Solving: A solver is the software that performs the calculations and computes the mathematical model. Depending on a model’s complexity, this step can require extensive computational resources and time.

Post-processing: This is the simulation output, such as data files, heat maps and charts. Some CAE platforms have built-in post-processors so engineers can view simulation results in the same program. If a solver doesn’t have a post-processer, engineers must download output files and load them into external programs to view results.

Some simulation software platforms integrate with external CAD programs for easy importing. Others provide CAD and CAE capabilities in a single platform, which streamlines workflows and helps engineers iterate faster. This also enables simulation-driven design. Regardless, once a model is ready for CAE analysis, engineers have options depending on what needs to be tested.

How to plan an engineering simulation

Here are the things to think about when planning a simulation study:

- What problem do you need to solve?

- How much time do you have to run the study?

- What computational resources do you have, and are they adequate for the study?

- What are your goals for the study, and what do you intend to do with the results?

- How will the results be communicated, and to whom?

Understanding the purpose helps engineers plan and run a simulation efficiently to minimize time, costs and other resources.