Large-format additive manufacturing provider to debut new robotic platform at Formnext 2024.

When it comes to additive manufacturing (AM), Caracol believes size matters.

Since its founding in 2017, the company has been pushing large-format additive manufacturing (LFAM) technology in the form of its Heron platform, which uses a six-axis KUKA robot to produce large thermoplastic composite parts via material extrusion.

Now, the company is making a foray into metal 3D printing with Vipra AM, a large-scale direct energy deposition (DED) platform that uses wire arc additive manufacturing (WAAM) to produce metal AM parts.

“At Caracol, we believe that the future of manufacturing lies in combining a strong application focus with advanced innovative technologies that reshape the capabilities of industrial production lines”, said Francesco De Stefano, CEO of Caracol AM in a press release. “With Vipra AM, we’ve leveraged the extensive know-how developed over years working on advanced process control and software for Large Format AM with thermoplastics and composites materials, to develop a proprietary cutting-edge metal platform that combines state-of-the-art hardware and software, with advanced robotic monitoring and automation.”

Caracol claims to have spent years developing projects and scaling parts production with Vipra AM, resulting in two configurations of the platform:

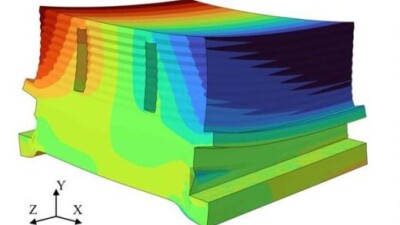

- Vipra XQ (Extreme Quality) uses plasma arc deposition and is designed to produce parts requiring both high strength and high precision. The system can process stainless steels and titanium alloys and is targeted at aerospace and energy applications, such as load-bearing brackets and other structural components, valves, gauges and structural piping connectors.

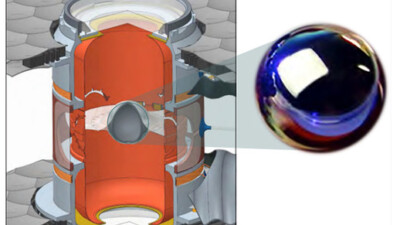

- Vipra XP (Extreme Productivity) aims for higher throughput in addition to being able to process aluminum and nickel-based materials as well as stainless steels and titanium alloys. The system is targeting transportation industries, including automotive components, aerospace pressure vessels and marine propellers.

“The launch of Vipra AM represents a significant breakthrough for the metal additive manufacturing industry,” said Gianrocco Marinelli, metal additive manufacturing director at Caracol, in the same press release. “In today’s competitive market, manufacturers face mounting challenges, from material waste and long lead times to the pressure of reducing costs while maintaining high performance. Vipra AM introduces cutting-edge capabilities and complements existing processes, enabling hybrid production models that combine legacy techniques with advanced metal deposition to help manufacturers optimize production lines, reducing waste, accelerating lead times, and driving overall efficiency without overhauling their entire operations.”

Vipra AM will be on display at Formnext 2024, with an official unveiling on November 19th.