Picture Perfect Pro Plan commits to minimum 85% uptime.

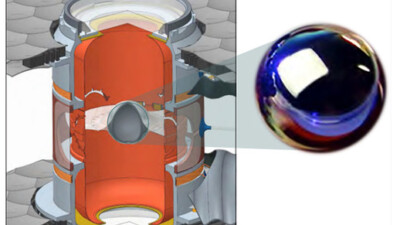

Just in time for this year’s Formnext in Frankfurt, Germany, Nikon SLM Solutions has announced redesigns of its SLM 280, SLM 280 Production Series and SLM 500 laser powder bed fusion machines. In addition to an exterior makeover, the machines have been upgraded with recoater brushes, so-called permanent filter modules and 700W lasers.

The permanent filter module is designed to trap soot in a sintered plate filter, coating the waste material with an inhibitor for dry disposal. According to the company, this increases machine uptime, stabilizes gas flow, reduces consumable costs and increases machine safety.

Alongside the redesigned SLM machines comes the launch of the Picture Perfect Pro Plan, an alliterative sales package for new machines in North America and Europe. Existing Nikon SLM Solutions customers can also opt into the new plan by renewing their service contracts for five years.

According to the company, Pro Plan benefits include:

- 85% Machine Uptime Commitment: Nikon SLM Solutions commits to a minimum of 85% uptime for mid-size and larger systems, including SLM 280, SLM 280 PS, SLM 500, and NXG series models. Beyond this minimum commitment, the company also claims success rates exceeding 90% uptime among installed base customers.

- Essential Production Items: All systems come with a handling device designed for safe and fast part handling. SLM 500 buyers receive an additional set of build cylinders.

- Five-Year Software Access: Continued access to SLM.Link, SLM.Quality, and Free Float software.

Additionally, the Pro Plan includes a tailored powder supply contract and a five-year service package. Nikon SLM Solutions claims that the first uptime commitment for mid-size and larger machines in the additive manufacturing industry.