Is there a path towards a truly integrated and collaborative manufacturing environment?

It is entirely possible that digital transformation, at least in discrete manufacturing, has reached an inflection point, as many efforts that were initially well-funded and well-managed are losing focus and momentum.

It might be time to reframe digital transformation discussions and implementations, with a dramatic shift in the focus of digital transformation away from inputs (“new and improved” and “faster, better, cheaper”) into measurable outcomes that fit smoothly into an enterprise’s business plans. This is nothing less than a reorientation of digital transformation and its enablement throughout an organization’s product lifecycle—from concept through end-of-life.

Nearly all industrial companies take digital transformation’s opportunities and implementation challenges very seriously. Management and leadership in a few laggard enterprises, however, still see digital transformation—or digitalization—as just a buzzword, even as they fall further behind their competitors.

A digital transformation tutorial

While it is clear to all within the PLM community that PLM is foundational for a meaningful digitalization strategy, senior leadership does not always understand this truth, leading to a paradox. The investment level in digitalization indicated by my organization’s research seems appropriate, yet success is in jeopardy.

Weak digitalization plans often reflect a need for top executives to be more aware of how much digitalization will potentially impact the jobs and responsibilities of everyone in the organization. Hence, well-thought-out integration and implementation strategies are mandatory. Also needed is the realization that digitalization is dependent on a strong and comprehensive PLM strategy, just as PLM is greatly enabled by digitalization. This synergy enhances the value of the resulting digital transformation initiative.

Fundamentally, digitalization is the next logical step in the ongoing revolution of representing anything and everything in 1s and 0s. This is to say that digitalization is moving from a fuzzy concept to a data-driven derailment of the status quo, including:

- Transforming products from physical goods into tangible services, the product-as-a-service (PaaS) business model that renders the “product” into data.

- As information’s importance continues to grow, products and services are increasingly bought and installed for the data they generate or collect.

- New sources of information are speeding up innovation and product development, adding urgency to digitalization.

It is important to remember that today’s PLM professionals were busy with applications and implementations decades ago when digitalization really was a fuzzy concept—PLM was here first, so to speak. The digital tools that were used to support the product lifecycle, which have now been in use for a few decades, were the beginnings of digitalization. What those tools can now achieve is essential to meeting today’s broad-based enterprise-level digitalization objectives.

What does digitalization mean? Digitalization transforms business models to generate new revenue and value opportunities; it is far more than an analog-to-digital change. If leadership struggles with this, explain it in 1990s terms as “knowledge management.” And make sure digitalization is not seen as merely scanning and digitizing paper documents into images. Images are losing their value and rationale as containers for today’s massive information flows. With the shift from documents to data well underway, containers, in any format, are falling short of the enterprise’s real needs.

Moreover, digitalization is not a one-and-done transformation, which can be demonstrated with a look at the history of recorded music. Analog music formats evolved from 45 RPM records with a single song on each side to vinyl long-playing (LP) media with several songs on each side, followed by cassette tape players, the Sony Walkman, and CDs. Music digitalization arrived as MP3 players with vastly improved sound and hundreds of songs. Now digitalization has taken music online to reach everyone through streaming services.

Likewise, digitalization is the next step in lifecycle management in leveraging existing and future technologies—not the starting point. Enabling digitalization requires end-to-end connectivity, end-to-end lifecycle optimization and sometimes deep changes in the organization and its work culture.

Why points of view matter

The fundamental task in getting anyone to “see” anything is to understand that person’s point of view and how they developed that way of thinking. The challenge with PLM-enabled digitalization comes when senior leaders perceive digitalization as different from and more strategic than PLM, and then allow independent, disconnected implementations. These initiatives are plagued by:

- Implementation gaps and overlaps

- Information resource duplications

- Extensions and integrations that leave some information requirements unsupported

- Independent and incompatible solution architectures

The results should surprise no one: Time-to-value and ROI are substantially diminished.

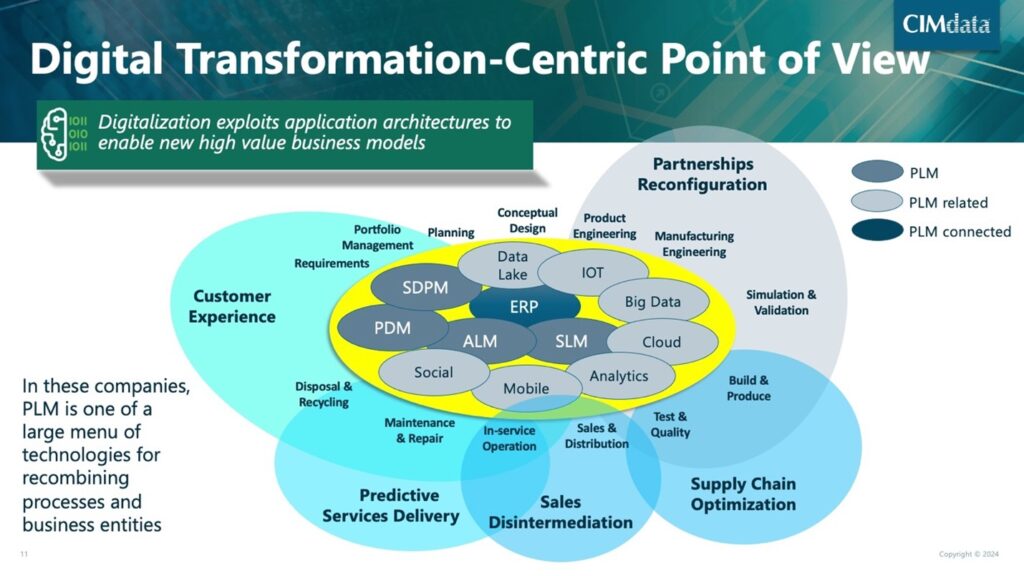

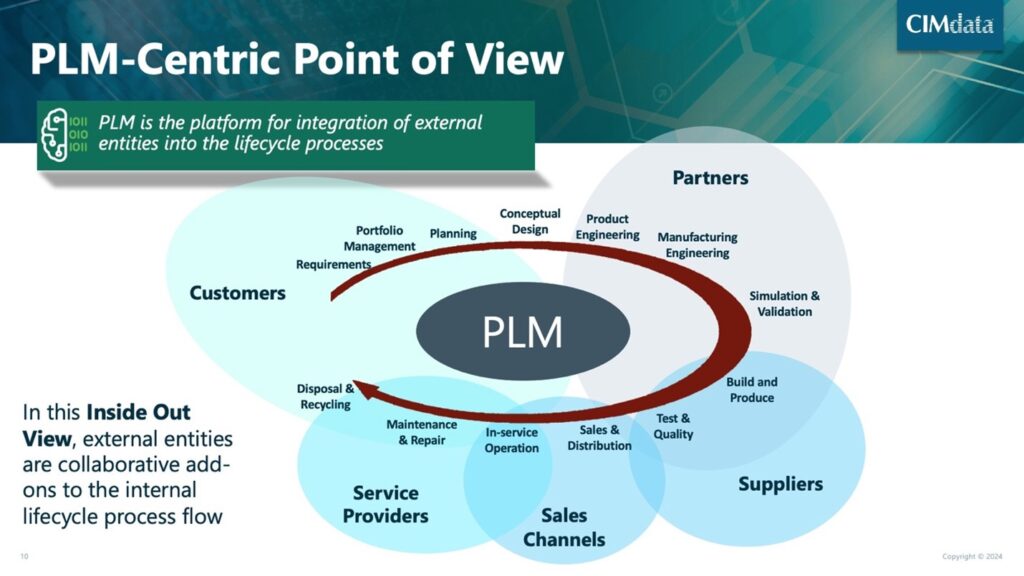

Points of view matter. To understand why, it helps to see the digital transformation-centric point of view as outside-in and the PLM-centric point of view as inside-out.

The outside-in view sees digitalization as strategically reconfiguring business functions and business entities. Relationships with and between external entities become opportunities for new value propositions, especially in predictive service delivery, sales disintermediation (reducing the number of intermediaries between producers and consumers),and supply chain optimization. With these implementations, the likeliest solution platform is enterprise resource planning (ERP), the go-to toolset for purchasing, supplier relationships, cost management and profit forecasts, among other resource-intensive activities.

From the PLM-centric, inside-out point of view, PLM is the platform for integrating external entities into lifecycle processes. In PLM, external entities become collaborative add-ons to internal lifecycle process flows. In this view, digitalization exploits the myriad application architectures used in product development and throughout the product lifecycle to enable new, high-value business models.

The take-away’s here are two-fold:

The digitalization community must recognize the power and necessity of a fully functional PLM platform—specifically that end-to-end connectivity and optimizing business functions and entities throughout the lifecycle are foundational to realizing their business and digital objectives.

The PLM community must appreciate the digitalization community’s view that strategically reconfiguring business functions and entities (not just “integrating” them) can result in major new business value propositions.

Both communities must be able to see the significant opportunities that lie at the intersection of their two perspectives.

PLM’s place in the enterprise’s digital landscape

PLM-enabled digitalization requires a deeper understanding of PLM’s role in the enterprise’s digital landscape. If a PLM-enabling product innovation platform is a viable way to enable the digital transformation of the lifecycle, it is then fair to ask: What is PLM?

After 40 years of working in and around PLM-enabling technologies, solutions and toolsets, PLM should be viewed as an end-to-end strategic business approach—a highly developed set of business solutions that are both internally and externally consistent and used for:

- The collaborative creation, use, management and dissemination of product-related intellectual assets. Assets here means all product/plant definition information, i.e.: the virtual product.

- All product/plant process definitions, including virtual planning, designing, producing, operating, supporting, decommissioning and recycling/disposal.

Understood this way, PLM is far more than an engineering-oriented technology for product development. It’s an innovation platform that supports the extended enterprise and all of its needs from concept through end-of-life.

And bear in mind that innovation takes place not only during the enterprise’s countless transformation processes but also in the very definitions of the organization’s intellectual assets.

Next, we should clearly understand what intellectual assets are: All the components of the enterprise’s product and process definitions. This means all mechanical, electronic, software, formulas, recipes, specifications and documentation components, plus all the business, manufacturing and support process definitions that fall within the scope of the end-to-end lifecycle.

What is meant by “product”? Another sweeping definition: discrete manufactured products, of course—aircraft, cars and trucks, computers and software and medical equipment, as well as mundane things like pills, furniture, hats and coats, shoes and socks, foods and soda pop (canned or otherwise) and on and on.

Fast forward to the 21st century, where companies and their leaders can no longer afford to focus solely on traditional discrete products. Today, the demand spans a wide array of projects and assets, including:

- Construction projects: Buildings, hospitals, bridges and highways.

- Processing plants: Oil refineries and offshore drilling platforms.

- Infrastructure assets and facilities: Airports, railways, distribution systems and their associated equipment.

- And much more: Spacecraft, weaponry, ships and beyond.

These “products” defined in all their endless variety and adaptations as the organization’s intellectual assets in the endless, i.e., circular, product lifecycles of development, production, marketing and sales and usage, support, upgrades and maintenance plus research for everything that comes next. Within these lifecycles, PLM is tightly linked (and usually integrated) with ERP, SCM, CRM and other enterprise solutions, as well as a myriad of product-definition and creation tools (e.g., computer-aided design, engineering, and so on).

Considering the above, it’s no surprise that information technology (IT) has been divided into two readily distinguishable parts. One part supports deliverable assets in the form of physical products managed with ERP and other similar solutions. The other part supports intellectual assets in the form of virtual products managed with PLM.

In turn, this IT division is leading to the formation of three distinct domains within digital transformation—PLM and ERP, of course, but increasingly execution. Execution is an all-embracing term for getting more competitive and innovative products, systems and assets (physical or virtual) into customers’ hands sooner while lowering overall costs.

And I see refocusing digital transformation efforts toward execution as a way for enterprises to stop punishing their capital structures.

Thus, digital transformation—digitalization—can yield a truly integrated collaborative environment at the heart of every organization that works to solve all common problems. This, too, is an inflection point.