Form 4L touted as world’s fastest large-format SLA printer.

Formlabs has officially announced the new large-format Form 4L and Form 4BL 3D printers as well as the opening of its SLS and SLA platforms. The company has also introduced new printer accessories, two new SLS materials, five new PreForm features and new post-processing solutions.

Form 4L: “Fastest Large-Format SLA 3D Printer in the World”

Formlabs is aiming to bring the high-speed capabilities of the Form 4 to a larger format with the Form 4L and a biocompatible version, the Form 4BL.

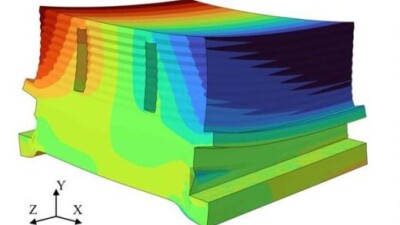

Built on the company’s next-generation Low Force Display (LFD) print engine, Formlabs claims the Form 4 has a 99% print success rate. With a build volume nearly 5x the size of the Form 4, Form 4L features include:

- Large-scale prints in under six hours, at up to 80 mm/hour printing speeds

- Nearly five times larger build volume than Form 4

- New cartridge design can reduce plastic waste by 63% and deliver faster resin dispensing

- Compatible with 23+ materials offering durable, rigid, biocompatible, flame retardant, and other application-specific properties

- Accessories: Resin Mixer, Resin Tank, Build Platform, Resin Pumping System and Finish Kit and Form Wash L for post-processing

“We believe in driving innovation forward by providing the freedom and flexibility users need to bring their ideas to life. Form 4L will enable users to solve bigger problems and bring big ideas to life at lightning-fast speeds, regardless of scale or complexity,” said Formlabs CPO Dávid Lakatos in a press release.

“One of the first things we printed on the 4L as soon as we got it was a seat for the Stingray Ride-On, and we used that exact 3D print in a vendor meeting,” said Agostino LoBello, Product Design Engineer at Radio Flyer. “The speed and dimensional accuracy have made a big difference in our shop.”

Form 4L is $9,999.

Formlabs platform open for developers

The company is also officially opening up its platform with the aim of giving users more control and flexibility. To complement Formlabs’ materials library, new software, integration options and material pricing is intended to put users in control to transform how they bring ideas to life. Formlabs claims that Developer Platform gives users new freedom and flexibility to tap into any material.

The new software and material pricing include:

- Open Material Mode (OMM) – Use any material with a license, no restrictions

- Print Settings Editor (PSE) – Adjustable print settings, free with every machine

- API & Integrations – Connect any software that you use to get a print started

- Lowered material pricing – $79 general purpose materials

- Bulk pricing for production – Bulk material pricing at $35 per liter for SLA resin and $45 per kilogram for SLS powders

“Formlabs started with a clear mission to make professional 3D printing more accessible, and opening our platform is the beginning of a new chapter for Formlabs, where we enable users to help make 3D printing better for everybody,” said Formlabs co-founder and CEO Max Lobovsky in the same press release. “Developer Platform represents a transformation for our entire platform that will unlock the benefits of user control and unique properties of third-party SLS and SLA materials. This shift will break down barriers, welcoming innovators at every level to explore endless new possibilities and bring their ideas to life.”

New materials and PreForm features

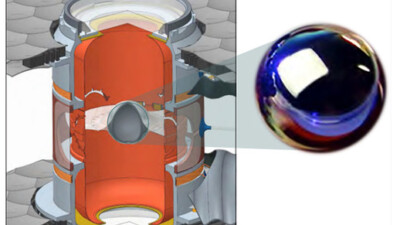

Formlabs also introduced new advanced SLS materials, Nylon 12 White Powder and Nylon 12 Tough Powder, to expand end-use part applications.

- Nylon 12 White Powder – Delivers the biocompatible material properties of Nylon 12 Powder in a formulation that produces high contrast and customizable white parts

- Nylon 12 Tough Powder – Offers best-in-class refresh rate among Formlabs’ Nylons combined with the ductility and dimensional accuracy necessary for producing highly resistant parts with reduced warpage

Finally, as Formlabs opens its platform, the company is also launching new PreForm software with what it says are highly-requested features for job model and preparation. These include:

- Shareable print settings: Users can share and apply fine-tuned print settings as FPS files.

- Job and model preparation features: model hollowing, drain holes, part texturing, part labeling, part cages