BMF material compatibility expansion includes 3D Systems’ Figure 4 HI TEMP 300-AMB.

Boston Micro Fabrication (BMF), a provider of micro-scale 3D printing solutions, is introducing four new materials for its microArch series 3D printers. The addition of these materials, including 3D Systems’ Figure 4 HI TEMP 300-AMB, BASF Ultracur3D 3280 and BMF resins HTF and SR, is intended to enhance BMF’s ability to meet material requirements in aerospace, medical devices, electronics and biotechnology.

By adding these materials to its existing lineup, BMF is aiming to enable engineers and researchers to create fit-for-purpose precision parts with greater accuracy, heat resistance and material performance.

4 new materials for micro-scale 3D printing

3D Systems Figure 4 HI TEMP 300-AMB is designed for extreme thermal environments. The production-grade, ultra-high temperature resistant plastic offers a Heat Deflection Temperature (HDT) of over 300°C. No secondary thermal post-cure is required. Figure 4 HI TEMP 300-AMB is suitable for HVAC components, motor enclosures and low-pressure molding.

“Boston Micro Fabrication’s micro-precision 3D printing technology has completely transformed how we approach connector manufacturing,” said George Glatts, Owner of Z-Axis Connector Company. “Previously limited to tolerances of 5 thousandths with traditional methods, BMF allowed us to achieve tolerances of 1 to 2 thousandths, opening new possibilities for compact, high-performance connectors. Their platform also enabled us to use 3D Systems Figure 4 HI TEMP 300-AMB material that can withstand temperatures up to 300°C, meeting the demands of standard electronic assembly processes, enhancing efficiency and allowing us to create more compact, innovative designs. With BMF, we’ve reduced time and costs while delivering precision and performance that surpass industry standards.”

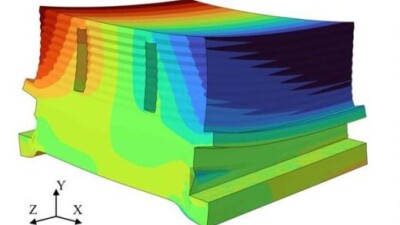

BASF Ultracur3D 3280 is a ceramic-filled resin with high stiffness (Young’s modulus of 10 GPa) and a high Heat Deflection Temperature (>280°C). Ultracur3D 3280 is suitable for tooling, molding and wind tunnel testing. According to BASF, its low viscosity and stable suspension make it both easy to handle and print, positioning it for high-temperature and high-stiffness applications.

“Before discovering BMF, Makuta struggled to find a cost-effective solution for prototyping due to the size and complexity of their molded parts,” said Taki Yamada, Director of Business Development at Makuta. “Traditional methods like aluminum or urethane molds often fell short in holding the required tolerances, and the expense of creating entirely new molds was prohibitive. Using BASF Ultracur3D 3280 on BMF’s microArch system, we were blown away by the impeccable finish and precision of the first 3D printed mold inserts we received. Not only were they able to reproduce intricate features flawlessly, but they also maintained the tight tolerances our projects demand.”

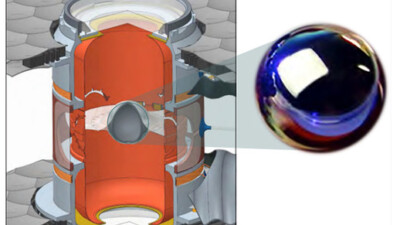

Designed by BMF, HTF (High-Temp) is a high-temperature resistant, tough and biocompatible resin. It is autoclave-sterilizable and suitable for applications requiring biocompatibility and flexibility. With an HDT of 152°C and compatibility with aerospace and biotech applications, HTF offers versatility across a range of environments.

Finally, SR (Sacrificial Resin) is a soluble, sacrificial material designed to enable the creation of single-use molds for parts produced with other materials that cannot be easily printed, such as polypropylene (PP) or polyoxymethylene (POM). According to BMF, this material opens new possibilities for prototyping and low-volume production by reducing the cost and complexity of micro-injection molding.