MobiPrint project envisions a future of on-demand accessibility.

Tired of having to get up and walk across the room to check on your latest 3D printing project? What if your 3D printer could come to you or, for that matter, go wherever it liked?

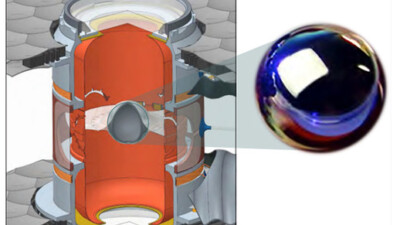

Meet MobiPrint, a mobile 3D printer that can automatically measure a room and print objects onto its floor. The system uses a graphic interface that lets users design objects for a space that the robot has mapped out. The prototype, which University of Washington engineers built on a modified consumer vacuum robot, can add accessibility features, home customizations or artistic flourishes to an indoor space.

“Digital fabrication, like 3D printing, is pretty mature at this point,” said Daniel Campos Zamora in a press release. Campos is a doctoral student in the Paul G. Allen School of Computer Science & Engineering. “Now we’re asking: How can we push it further and further into the world, and lower the barriers for people to use it? How can we change the built environment and tailor spaces for peoples’ specific needs — for accessibility, for taste?”

The prototype system can add accessibility features, such as tactile markers for blind and low-vision people. These might provide information, such as text telling conference attendees where to go, or warn of dangers such as staircases. MobiPrint can even create a ramp to cover an uneven flooring transition. It also allows users to create custom objects, such as small art pieces up to three inches tall.

Before printing an object, the system autonomously roams an indoor space and uses LiDAR to map it. The team’s design tool then converts this map into an interactive canvas. Users then can select a model from the MobiPrint library — a cat food bowl, for instance — or upload a design. Next, the user picks a location on the map to print the object, working with the design interface to scale and position the job. Finally, the robot moves to the location and prints the object directly onto the floor.

The current design uses PLA, and the researchers are working to have MobiPrint remove objects it’s printed and potentially recycle the plastic. They’re also interested in exploring the possibilities of robots that print on other surfaces (such as tabletops or walls), in other environments (such as outdoors), and with other materials (such as concrete).

“I think about kids out biking or my friends and family members who are in wheelchairs getting to the end of a sidewalk without a curb,” said Jon E. Froehlich, a professor in the Allen School. “It would be so great if in the future we could just send Daniel’s robot down the street and have it build a ramp, even if it was working just for a short period of time. That just shows you how reconfigurable environments can be.”

The team’s research is published in the proceedings of this year’s ACM Symposium on User Interface Software and Technology in Pittsburgh.