Solvent-free resin offers the potential for biodegradable implants.

In digital light processing (DLP), solvents are generally taken to be a necessary evil: necessary because they’re needed to reduce resin viscosity and layer-dependent crosslinking, evil (okay, maybe that’s a bit of a stretch) because they often reduce dimensional accuracy due to shrinkage while contributing to residual stress during evaporation.

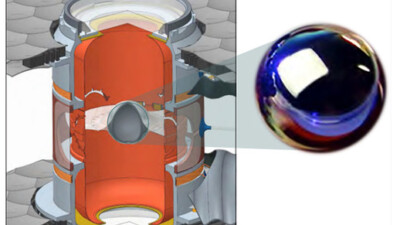

Fortunately, researchers at Duke University have come up with a new solvent-free polymer resin specifically designed for DLP printing. According to the researchers, this not only eliminate the shrinkage problem but also results in improved mechanical properties of the part while maintaining its ability to degrade in the body.

“I wanted to create an inherently thin, low-viscosity material for DLP to use for degradable medical devices,” said Maddiy Segal, a MEMS PhD candidate at Duke in a press release. “It took a lot of attempts, but eventually I was able to identify optimal monomers and a synthetic technique to create a solvent free polymer that can be used in a DLP printer without any dilution.”

Being one of the first solvent free resins that can be used in DLP printing, Segal was interested in testing the properties of parts made with it. She was excited to discover that the test parts did not shrink or distort at all and, in general, they were also stronger and more durable than those made with solvents.

According to her findings, this is one of the first empirical demonstrations of increased mechanical properties from eliminating solvent use in DLP 3D printing of degradable polymers.

To create the new polymer, poly(allyl glycidyl ether succinate) (PAGES), Segal and her colleagues analyzed the structure and properties of existing resins and modified the monomers and chain length in a step-by-step empirical approach to achieve the desired low-viscosity polymers. In total, she experimented with about 60 different combinations before finally making the product she had been hoping for.

“Besides making a material that didn’t shrink and was stronger, I also wanted it to be useful for medical applications,” Segal said. “I’m trying to make prototype devices that are both biocompatible and degradable. Eliminating toxic solvents from the process will help me do that.”

Segal’s ultimate goal with this work is to apply this technique to biodegradable medical implants. Devices fabricated from PAGES could be implanted and designed to degrade naturally over time, eliminating the need for additional surgeries to remove them. It could also potentially be used as a bone adhesive to hold fractures together temporarily or in soft robotics applications, where a soft, degradable material is needed, Segal added.

“This kind of material is what makes this particular application the primary goal of my work,” Segal said. “And in reality, this technique could be used for any sort of implant that you would want to degrade after some time and not stay there forever.”

The research is published in Angewandte Chemie International Edition.