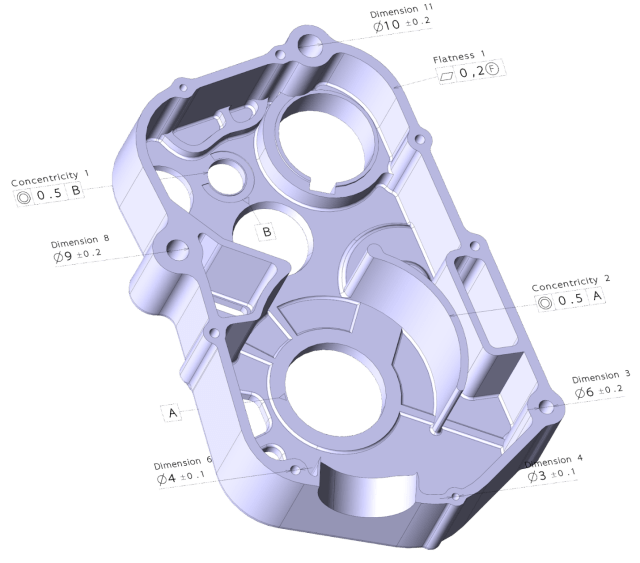

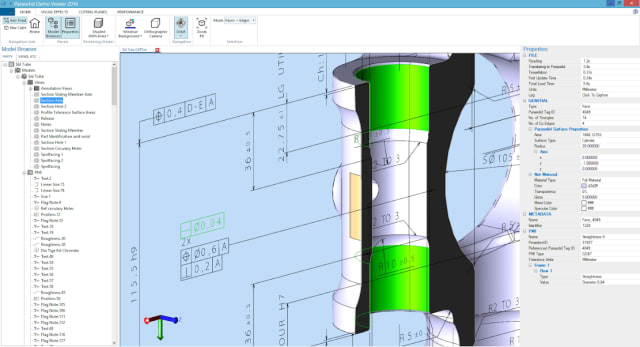

It starts with being able to read CAD geometry and data in all formats.

Metrology has long played a crucial behind-the-scenes role in the production of manufactured objects that make up the world around us.

Nearly every product—from the simplest consumer electronic to the newest and most sophisticated automobile—contains parts and components that need to fit together and there is very little room for error.

Manufacturers, eager to make their product development processes as efficient as possible, rely on metrology to conduct measurements and inspections that can detect any defects early in the process.

For metrology software vendors, the ability to best serve manufacturing customers in achieving these goals has required constant evolution and over the past decade, they have adapted their offerings accordingly—but more challenges remain.

The Evolution of the Market

One of the biggest changes metrology vendors have adjusted to over the past 5-10 years has centered on the importance of supporting a multitude of 3D CAD file types from a variety of CAD applications.

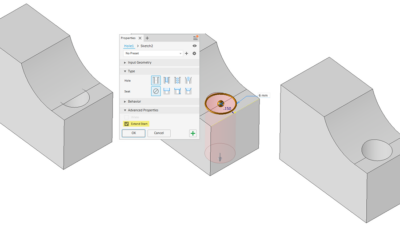

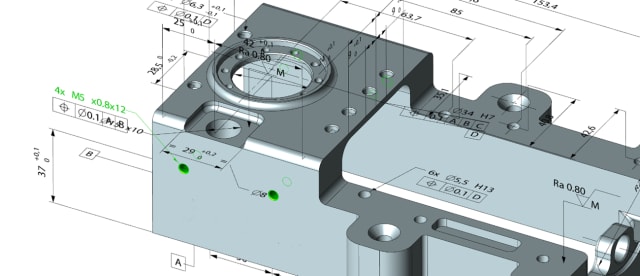

Metrology software must rapidly compare points read from a multi‐axis probe, vision system or laser scanner to the surfaces described in the original CAD file for the part or component.

But accurate measurement requires access to good data. This is impossible if the CAD data to which the measurements are compared is inaccurate. The metrology market responded to this need by enabling a large variety of CAD formats to be read from the native files. This provided access to quality 3D CAD data and enabled more inspection data to be processed.

While contending with CAD formats of all sorts, metrology vendors simultaneously had to simultaneously grapple with new sources of data, such as the Internet of Things (IoT), the cloud and mobile devices.

Metrology software had traditionally resided on the desktop in close proximity to the measuring device, but this changed to accommodate these new technologies.

Once these challenges are met, what challenges lie ahead over the next decade?

Tackling a Talent Shortage

One of the first challenges to address has nothing to do with software per se, but concerns the people who develop it.

Simply put, there’s a fierce war for talent right now—and one of the biggest challenges metrology software vendors are wrestling with is finding, hiring and retaining people with a very specific set of knowledge. They need people with knowledge in many fields, including robotics, kinematics and numerical mathematics, as well as more generalized metrology knowledge. Finding good people is not as simple as hanging up a “help wanted” sign.

Striking the Right Balance

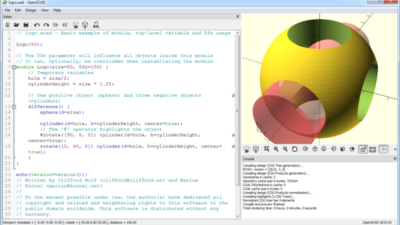

Meanwhile, the need to support a multitude of CAD formats has only grown. There’s an increasing recognition that open-source—rather than proprietary—software is the way to go. As much as vendors might want to monopolize the market, there will always be multiple viable players operating in the space. This only reinforces the importance of being able to seamlessly communicate and work with other people and other devices, which means the ability to support ever-increasing data formats.

At the same time that metrology vendors are adding more functionality to their products and making them increasingly powerful and complex, there is a growing premium on user-friendliness. Users expect to be able to get up and running with a product quickly—no matter how powerful or feature-rich it might be.

Innovative vendors are responding with intuitive, user-friendly products that don’t require end users to have a hundred-page manual and hours of training to learn how to work with it—and they deliver this user experience without sacrificing any functionality. For example, take industry veterans Hexagon and its application Inspire or market newcomers Eleven Dynamics and its Nexos 4.0 product. Both providers have been successful in striking a balance between adding increased functionality and providing powerful user-friendly applications.

Dealing with Data

Additionally, the nature of measurement itself is evolving. Noncontact scanning, rather than tactile probing, is the current direction of the industry, as evidenced by the metrology equipment most commonly being purchased and deployed. This trend toward scanning means there is lots of data to handle, which in turn has several implications.

For starters, the ability to visualize all that data properly requires powerful graphics support to ensure realistic 3D visualization of metrology workflows. There are also implications for the great cloud versus desktop debate. When dealing with metrology hardware that is generating huge amounts of data for processing, just getting that data to travel to a laptop or desktop in a speedy manner via a USB cable is its own challenge. Having it make a round trip through a network to an image on a screen is a whole other problem.

For that reason, there will continue to be opportunities in the market not only for carefully architected desktop and cloud metrology offerings but also hybrid solutions. Where on-premises software initially makes the data, other functions like reporting or analysis are performed in the cloud. This type of hybrid solution was recently echoed by David O’Neal, a product manager with Hexagon Manufacturing Intelligence, when questioned about the near-term future of metrology applications.

The Next Chapter

How will metrology software vendors respond to these trends and navigate these various challenges over the coming decade?

Fortunately, they don’t have to do it alone. Third-party SDKs—particularly those that support fast and accurate 3D CAD data access and powerful 3D visualization on desktops, mobile devices or the web—can help vendors evolve their offerings to keep pace with the market while freeing up the bandwidth of their software development resources during a tight labor market.

In the decades to come, just as in decades past, metrology applications will be judged by the quality, power, speed and automation of the software that drives them. By choosing the right software toolkits to build upon, vendors can successfully adjust to the challenges of a changing manufacturing environment and write the next chapter of metrology software.