3DEXPERIENCE Make manufacturers can install custom quote/ecommerce engine by DigiFabster on their sites.

3DS Store has sponsored this post.

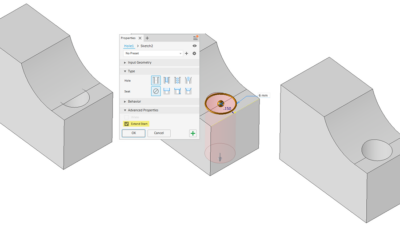

Push-button manufacturing—the ability to push one button and send a design to a manufacturing service—is one step closer with the team-up of Dassault Systèmes’ 3DEXPERIENCE Make, the online marketplace of manufacturers, and DigiFabster.

Design engineers have used the 3DEXPERIENCE Make marketplace for the manufacture of parts, whether they are 3D printed, CNC machined, laser cut, bent out of sheet metal or injection molded. They can receive bids from any or all of the manufacturers in the online marketplace. The chosen manufacturer will make the part and send it to their door.

However, as many design engineers know, a procurement process can slow down when the cost of the part needs to be manually quoted. That is often the case when parts must be machined, cast or bent. This is where the engineer has to exit the express lane onto a side street in heavy traffic. Busy vendors need to study the design to determine the cost. They promise to get back to you, but now the engineer is at a red light waiting for it to turn green. Engineers must wait for the quotes. If they get lucky: a low quote and next day delivery. But in reality, what happens next is quotes that come in as they fit the schedule of each vendor. You might end up with no quotes, or too many.

While this process may be an advantage over the days when one would have to search for manufacturing services by thumbing through volumes of the Thomas Register for American Manufacturers, and the methods of today—Google searches—both methods stall when the manufacturer says, “Call for a quote.”

You don’t have to call for a quote with online marketplaces, like 3DEXPERIENCE Make.

A manufacturing service that can dispense with the wait by using an instant quoting engine, a service that is able to tell you how much a part will cost right away—without human intervention—and is able to give you the cost of a part made by all the processes it offers, not just 3D printing, would have every advantage in the 3DEXPERIENCE Make marketplace.

This comes as no surprise to Mike McCumber, lead marketing manager for DigiFabster, who recognizes the typical engineer’s aversion to picking up the phone to make a call or waiting for quotes to come in.

“Customers are multiple times more likely to buy from a vendor with instant quoting than from a vendor with call-for-quotes,” he says.

And when timing is critical, cost takes a back seat. “80 percent of the time, the first company that provides a quote gets the business,” says McCumber.

Who is DigiFabster?

One cannot expect every machine shop or tool and die maker to have IT and developers onsite, and perhaps not even in their contacts. Tech startups conceived as code have a big advantage in an online marketplace.

DigiFabster aims to level the playing field.

DigiFabster was founded by Konstantin Ivanov, who functions as the company’s CEO. Ivanov, a developer, operated a 3D printing service bureau when 3D printing came into vogue in the year 2000. He added CNC to round out his service. After writing the software that provided instant quoting and ecommerce, Ivanov chose to expand his business by productizing the quoting/ecommerce engine he developed, and founded DigiFabster.

“Think of an ecommerce engine that promises a sales interface to the customer and can take an order 24/7,” says Ivanov. “But quoting a part, knowing how it’s going to be printed or cut, DFM [design for manufacture] … that’s complicated. The typical ecommerce engine doesn’t do that. We can, though. We can estimate the price with a specific technology and provide them with a nice, simple interface so they can see the price paid for the order and track the status on the board. It’s as easy as ordering pizza.”

Companies can use their ERP systems to estimate the cost to manufacture a part, but manufacturing services seldom have the five to six months it takes to onboard an ERP system, says Ivanov.

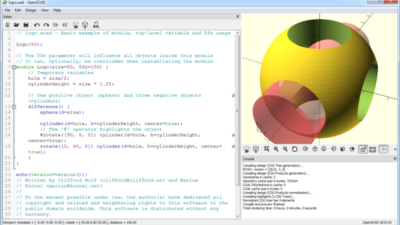

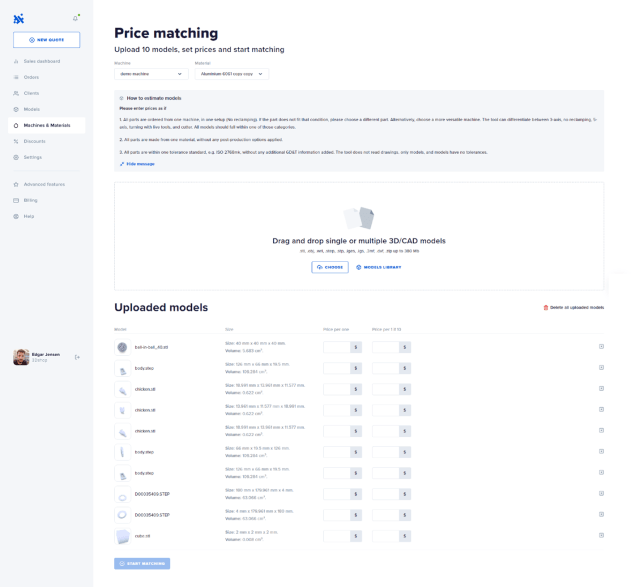

“We decided from the beginning to make sure that for our customers the onboarding is really, really simple,” says Ivanov. “We came up with a tool called Price Matching, which basically asks the customer to upload 10 models with cost to manufacture each of them in quantities of one and one hundred parts.”

Customers drag and drop their model files into the Price Matching interface, which also gathers the shop’s specifics. DigiFabster will take the data supplied and create an algorithm that is kept on the cloud and accessed by the customer by a single line of code in their web page.

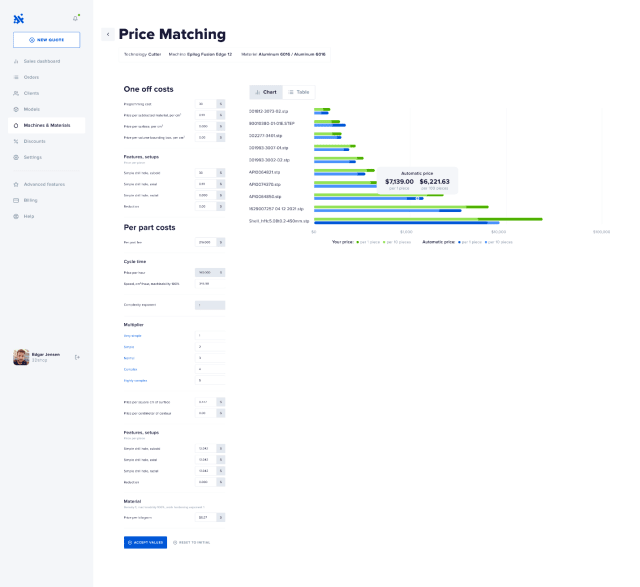

“It’s only an I-frame. That is DigiFabster at its easiest set up,” says McCumber. “But for those shops that obsess over pricing, they can tweak a hundred parameters.”

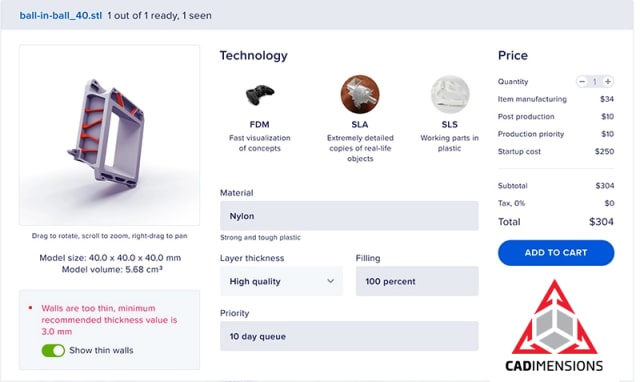

The manufacturing service adds specific information, such as cost of local material, profit margin, type of machines used, labor rated, etc., and voila, they have joined as another vendor in 3DEXPERIENCE Make with instant quoting. They also get a bump in their perceived tech savviness—they can now claim they are making use of AI.

DigiFabster interpolates and extrapolates for different quantities. That should be easy enough mathematically, but their real genius is being able to determine the price of similar products—without laborious calculations of tool paths, idle time, etc. and even more laborious human intervention.

How accurate is the estimate?

“It’s not so much about getting the price right as it is about getting the price quickly,” counters McCumber. “Our most successful customers have proven that growing their business is done more rapidly by winning business versus obsessing over the final 3-5 percent of quoting accuracy.”

Still, DigiFabster claims 99 percent accuracy in the cost of 3D printed parts. For CNC parts, the accuracy of 90 percent.

Ease of Implementation

While DigiFabster writes all the code, it is still up to the manufacturing service to install it on their website. A mom-and-pop machine shop, with no programming tools in their toolbox, will wonder how hard DigiFabster is to implement.

McCumber would assure them that it is not hard at all. They already have a website, or they might hire someone to create it. “It’s a simple matter for them to take the iFrame we generate and put it into the webpage,” he says.

“We have customers up and running in an hour, or half a day if they want to implement the ecommerce,” he assures. “We want the DigiFabster module to be self-service, so we’ve really invested a lot of time and technology resources to make setup really easy.”

Powered by DigiFabster?

For all that DigiFabster does—and it is nothing short of miraculous, bringing metal cutting machine shops into the modern age—it’s quite remarkable that they don’t make a big deal out of it. You have to squint really hard to see a hint of “powered by DigiFabster” on a site that has installed it.

The company seems content to be white labeled and work behind the scenes.

“We’re providing a service to our customers,” says McCumber.

Pricing of DigiFabster

True to the you-don’t-have-to-pick-up-the-phone attitude its application allows, you don’t have to call DigiFabster to learn how much it costs, either. The pricing is conveniently available on DigiFabster’s website. You can get DigiFabster by the module ($250 per month for each of 3D printing, CNC milling and CNC lathe/turning or 2D cutting). Getting all modules at once (3D printing, CNC milling and CNC lathe/turning and 2D cutting) plus additional enhancements will cost $840 a month. A full year’s commitment is required in either case.

Never has the cost of modernizing your machine shop been this low or as convenient.

To learn more, visit Digifabster.