Jim Anderton comments on the sea change in additive manufacturing seen at the 2022 RAPID+TCT event in Detroit.

Episode Summary:

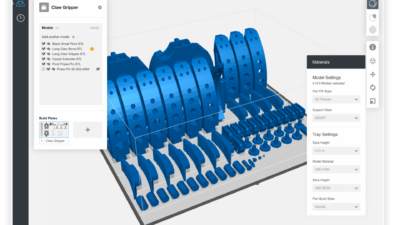

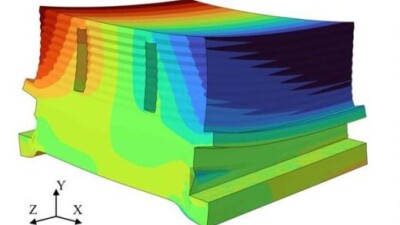

Whether you call it 3D printing or additive manufacturing, the technology that lets almost anyone create highly complex part shapes from filaments, liquids and powders has spawned an entirely new industry. Once thought to be the successor to subtractive manufacturing technologies like machining, additive has evolved into a part making technology with a fundamental difference: the ability to make shapes that are completely impossible to build in any other way. But for the 20 or so years that additive has been a commercially available technology, the primary criticism has been about scale. “3D printing is great for small volumes, but not for mass production”, said the detractors.

At this year’s RAPID+TCT event in Detroit, engineering.com’s Jim Anderton found a new attitude post Covid: additive as a production ready, off-the-shelf and well understood technology. And end users from industries as diverse as surgically implantable materials and aerospace, agree.