AM Forward promises to change the way large manufacturing companies deal with suppliers.

It’s no secret that the state-of-the-art in manufacturing technology varies widely by industry sector and by enterprise scale. Large, R&D-heavy OEMs in the automotive, aerospace, energy and defence sectors have access to and implement the latest technologies, such as advanced additive manufacturing. The supply chain that supports those companies, however, have varying abilities—from capability that matches that of their customers’, to reliance on third-party and frequently offshore expertise.

The AM Forward initiative, backed by the Bipartisan Innovation Act, aims to commit large U.S. companies to purchase 3D printing parts from smaller U.S.-based suppliers, as well as train those suppliers on new technologies and provide technical assistance. If successful, the program could change the traditional relationship between large manufacturers and the entire supply chain.

Access all episodes of This Week in Engineering on engineering.com TV along with all of our other series.

Transcript of this week’s show:

To see any graphs, charts, graphics, images, and/or videos to which the transcript may be referring, watch the above video.

Large, sophisticated manufacturing firms have been a cornerstone of economic development throughout American history. From the interchangeable parts of Springfield muskets to Henry Ford and on to the Space Shuttle, the history of technology-heavy manufacturing firms in America is essentially the history of the United States.

What is rarely considered, however, is the huge network of Tier 1 and Tier 2 suppliers that make the component parts and subassemblies that go into our autos, airplanes, energy infrastructure and consumer goods. And since the 1970s, outsourcing of design engineering and manufacturing capability to the supply chain has been the favoured path toward profitability.

At least it was, until COVID and now war in Ukraine. The resulting fractured supply chains have crippled multiple industries, especially the automotive sector, with no clear end in sight. Compounding the problem is the increasing gap in technical capability between large, well-funded OEMs and the smaller companies that make up the majority of the supply chain.

Fixing this problem is complex, but a major imperative is to reduce reliance on offshore suppliers, particularly in Asia. To achieve this, new American small and medium-size manufacturers must emerge, and the existing base has to modernize.

The Biden Administration has taken a first step toward achieving this long-term goal with the announcement of AM Forward, which is, according to the White House, “a voluntary compact between large, iconic manufacturers and their smaller U.S.-based suppliers.”

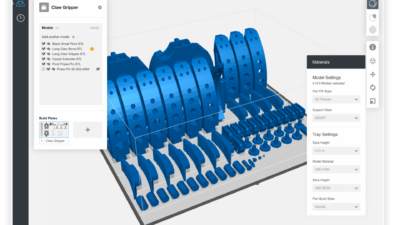

What’s in the voluntary compact? The five founding industry heavyweights are publicly committing to purchase parts made with additive manufacturing from smaller domestic suppliers, provide additive manufacturing training for the employees of those suppliers, provide technical assistance to supplier companies and to work toward common standards and certification for additive technologies throughout the supply chain.

While this would seem to be a logical development considering global supply chain difficulties, it also addresses the serious barriers that have slowed widescale implementation of additive in American manufacturing. The primary issue has been uncertainty. The costs for small and medium-size supplier companies to develop additive capability and production scale are considerable, in hardware, software and training.

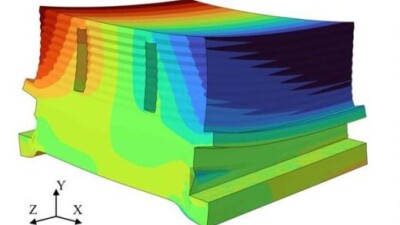

Without guaranteed markets for parts at production volumes that generate a sensible return on investment, the risk of making the move toward production additive has been too great for many supplier companies. And for the companies that do want to take the plunge, the gap between the knowledge base held by large customers and their suppliers can be enormous. 3D printer manufacturers and material suppliers can deliver the knowledge necessary for smaller companies to learn how to effectively use the equipment, but the ability to make production parts with the accuracy and precision needed for high-technology customers in sectors such as automotive, aerospace, medical and energy is another level of sophistication generally nonexistent among smaller suppliers.

AM Forward is joined in the effort by multiple U.S. Federal agencies. To facilitate access to capital for small and medium-size manufacturers, programs are developing within the U.S. Department of Agriculture, the Small Business Administration and the Export-Import Bank. For technical assistance, the Department of Defense and the Department of Energy will help with funding and testing facilities. For training, the DOD-sponsored America Makes and the U.S. Department of Labor will help manufacturers establish apprenticeship programs for additive manufacturing. The Commerce Department, through the National Institute of Standards and Technology, will work with the ISO, ASME and ASTM International to establish industry standards and process certifications.

While multiple Federal agencies are involved, a key feature of AM Forward is that the compact is managed by a non-profit organization, the Applied Science and Technology Research Organization of America, or ASTRO America, based at the Rock Island Arsenal in Rock Island, Illinois. The initiative is open to any OEM. The five major corporations that are anchoring the project? They are GE Aviation, Siemens Energy, Honeywell, Raytheon and Lockheed Martin.

That’s a heavyweight list, but the great unknown is how fast small and medium-sized American manufacturers can develop meaningful production capacity and capability, and how well the multiple government departments can deliver the essential services that smaller companies need. This is a full-court press, and if it works, the result could be a new Renaissance for American manufacturing, with hundreds of thousands of well-paid jobs created and a fundamental shift away from trans-Pacific sourcing of parts and components.