This GM supplier prints casting cores out of sand to produce complex, lightweight underbody components for the Cadillac Celestiq electric sedan.

Tooling & Equipment International (TEI), a Livonia, Mich.-based casting core supplier to General Motors, is using the world’s largest 3D sand printer to produce cast cores for the series production of large-format, weight-saving underbody structural components for the Cadillac CELESTIQ luxury all-electric sedan.

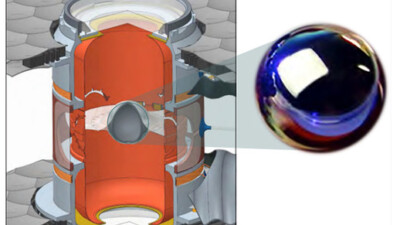

TEI produces highly complex castings for the engineering and manufacturing industry and has been working with Voxeljet sand printers since 2018, starting with a three-year volume contract of more than 500,000 liters of 3D-printed sand. Voxeljet’s VX4000 3D printers are among the world’s largest 3D sand printers with a build volume of 4 x 2 x 1 meters.

Casting replaces 40 components

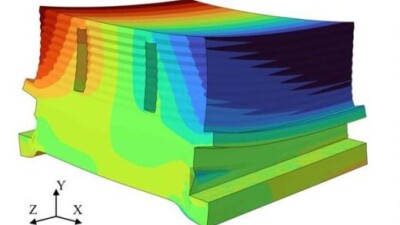

The underbody structure consists of six precision sand-cast aluminum parts. To produce these complex structures as economically as possible and with the lightest possible weight, TEI uses additive manufacturing to make inner cores. This way the company can incorporate stiffening features into the hollow sections, which would be very expensive with conventional manufacturing.

A total of 51 additively manufactured sand cores are used in the production of each vehicle underbody. TEI prints these using VX4000 printers, each of which prints hundreds of inner cores for several vehicle sets in a night.

After printing, the cores are smoothed, coated with a fireproof coating, placed in sand molds and finally cast using a low-pressure filling process. Each of the six castings reduces the number of parts by 30 to 40 components compared to typical stamping processes.

As each structural part has fully machined interfaces, the six castings can be assembled precisely to very tight tolerances for assembly.

“By eliminating tools and taking advantage of the large build volume of the VX4000 printers, we can significantly reduce delivery times and produce lightweight components with optimized topologies. This would not be possible in the conventional way,” says Oliver Johnson, President of TEI.

Johnson adds that 3D sand printing makes it possible to produce completely new designs and develop lightweight structures to produce geometrically optimized parts, which automotive and aerospace OEMs can easily integrate into an existing production process.