Understanding simulation for 3D printing and its benefits for engineers.

The are few items in the engineer’s toolkit with more practical value than simulation.

Grouped under the broad heading of computer-aided engineering (CAE), simulation involves a host of other acronyms: finite element analysis (FAE), computational fluid dynamics (CFD) and multibody dynamics (MBD), to name a few. While these tools were originally used at the end of product development, over time they have become an integral part of the design process.

Simulation helps us understand complex thermomechanical phenomena without the need to produce physical prototypes, saving both time and money. In this regard it shares a commonality with 3D printing, which is often lauded for its ability to reduce the time and capital expense of prototyping.

What is simulation for 3D printing?

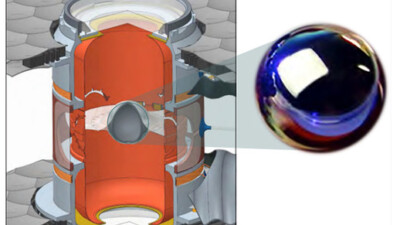

While the tools of simulation are often focused on parts, in the context of 3D printing, simulation is more often focused on processes. That means simulating material flow, heat distribution and mechanical stress, among other factors. Typical 3D printing simulations include static analysis to identify deformation based on stresses and strains, dynamic analysis to account for noise, vibration and acceleration; and multibody dynamics for evaluating stress on multidimensional assemblies.

The goal is to understand the physics involved in the layer-by-layer progression of a build and how these will in turn affect the final product. Ideally, simulation enables additive manufacturing engineers to predict the microstructural characteristics of 3D printed parts and thereby anticipate potential issues, such as warping, residual stress or support structure failures. In addition, simulation can be used to improve print speeds or reduce necessary post-processing operations.

What are the simulation outputs for 3D printing?

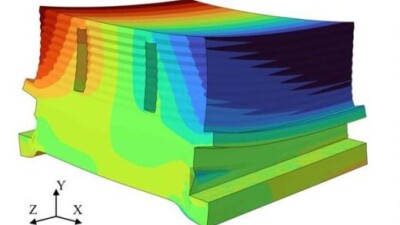

The two most common outputs of additive manufacturing simulations are temperature distribution within the build volume and mechanical deformation within the part. Depending on the application, these two outputs can potentially be calculated independently although there is obviously a high correlation between them.

For example, some software packages will allow the temperature gradient to be computed on its own, which is considerably faster than a running full simulation of the entire 3D printing process. As a bonus, at least in the context of 3D printing, solving heat issues can sometimes solve problems with mechanical deformation at the same time.

Simulating deformation is generally more involved because it requires knowledge of the mechanical and thermal properties of the material. As is typical in simulation more broadly, simulating deformations in 3D printed components is more of a balancing act with regard to the size of the mesh: a finer mesh yields more precise results but it also takes longer to run.

Recoater interference is another common simulation output in 3D printing, though only for powder bed processes. With these technologies, such as selective laser melting (SLM), selective laser sintering (SLS) and electron beam melting (EBM), the recoater can physically impact deformations along the z-axis that are larger than the layer thickness, disturbing the part and most likely ruining the build. For this reason, some software packages include settings for recoater tolerance, generating alerts if z-axis deformations exceed a preset threshold.

There are also software packages that allow for simulating certain post-processing operations, such as heat treatments, detaching parts from the build platform and support removal. With regard to supports in particular, engineers can either simulate parts before generating supports to identify critical areas of deformation or internal stress or after generating supports to evaluate their impact on part dimensions and ensure that they’re still within tolerances.

That covers the basics of additive manufacturing simulation, but there’s much more to consider in terms of software selection, optimization, monitoring feedback, and more. Stay tuned for future articles that cover these topics in more detail.