An engineering primer on simulating metal 3D printing processes.

Given the unique characteristics of additive processes and the large number of parameters that can impact material properties and part performance, good design in 3D printing depends on good simulations of additive manufacturing (AM) processes.

While there are commonalities between AM processes and more traditional fabrication methods, such as laser cutting, the best approach to AM simulation involves developing a robust process-property-performance chain that’s specifically tailored to 3D printing.

Unfortunately, at least in the case of metal 3D printing, there remains a distinct lack of AM model verification and validation, a problem specifically identified in the American National Standards Institute (ANSI) latest Standardization Roadmap for Additive Manufacturing. The National Institute of Standards and Technology (NIST) has been working to develop a dataset that can serve this purpose, primarily through its Additive Manufacturing Benchmark Test Series (AM-Bench).

What data is needed for additive manufacturing process simulation?

NIST has identified several important datasets for verifying and validating AM simulation. These include:

- Powder packing, spreading and distribution: How metal powder spreading, placement and dynamics affect AM process quality

- Measurement Data: Particle position and velocity field tracking in 2D; Characterization and quantification of powder denudation and its effect on solid material consolidation

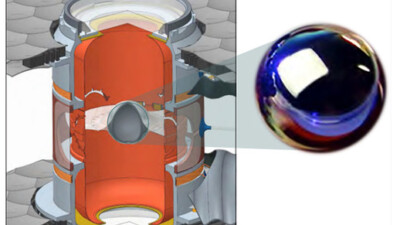

- Melt-pool-scale models: Complex physics involved in laser-materials interactions, including optical energy absorption, heat conduction, metal vaporization and local gas dynamics, molten metal fluid flow and nonequilibrium solidification dynamics

- Measurement Data: Melt pool imaging and thermography for solidification temperatures, gradients and melt pool cooling rates; Dynamic and directionally resolved laser reflectance, absorption and metal-vapor plume interaction; Single melt track, multi-track and 3D part surface topography; Cross sectional microscopy of melt pools

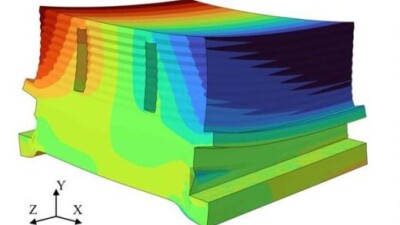

- Part-scale-models: Physical or computational assumptions which reduce fidelity to enable simulation of the full 3D printed part, including dynamic and location-specific thermal heterogeneity, residual strain and part distortion and microstructure evolution

- Measurement Data: Meso-scale in-situ thermographic measurements; Dynamic residual strain, Static residual strain and part distortion

- Hybrid physical and data-driven models: Newer classes of models that use machine learning to synthesize large volumes of measurement data and high-fidelity simulation results into models for faster, more computationally efficient simulations

- Measurement Data: Integrates all of the data above from the powder-level, melt-pool-level (a.k.a., meso-level) and part-level, along with instrument and machine calibration metadata

Given the sheer variety of data involved in AM processes, it should come as no surprise that AM models are currently calibrated or validated against a diverse array of measurements and that the approaches used to compare those measurements are similarly diverse. The moral here is that AM engineers need to settle on which data features or metrics are most important or, more specifically, which ones can be extracted from both models and measurements to provide a suitable statistical analysis framework for calibrating and validating AM multiphysics models.

Why simulate AM processes?

There are several types of AM-specific process simulations that can help improve 3D printed part quality by predicting distortions, porosity, and microstructural evolution.

Distortion simulations are useful because at least some distortion is almost always inevitable in metal 3D printing, especially when designing complex geometries. Distortion simulations can help minimize the amount of necessary post-process machining and reduce the risk of excessive stresses.

Porosity is a well-known issue in metal AM, since it can increase stresses in particular regions of a part and, if present in an already stressed region, it can accelerate performance deterioration and result in premature failures. Moreover, since AM process parameters are typically optimized using coupons or test parts with simple geometries, such as cubes, porosity is more likely to occur when printing more complex geometric features. For this reason, simulation is often more useful than simply printing geometrically simple coupons for statistical analysis, as it can help identify regions in complex parts where porosity is likely to occur.

Microstructural simulations of AM processes are difficult, but also highly valuable, since a part’s thermal history has a significant impact on its resulting microstructure, both in terms of its grain morphology and its phase content. These in turn affect the part’s material properties, such as Young’s modulus, isotropy/anisotropy, yield point and fatigue behavior. The difficulty lies in modeling microstructure evolution at high fidelity, since doing so is computationally intensive, especially if applied to entire parts. For this reason, microstructural models will often use simplified methods, such as cellular automata or phase transformation equations, speeding up predictions of microstructural properties at the meso level.

For each type of AM process simulation, but particularly for microstructural simulations, machine learning offers the potential to account for complex interactions between numerous parameters at multiple levels. However, as the AM-Bench efforts make clear, there is still a need for better test data on which to train machine learning models for AM process simulation.