New additive technologies are evolving all the time. Choosing the right one, and making it pay, means paying attention to technical and financial considerations.

This episode of The Engineering Roundtable is brought to you by Evolve Additive Solutions.

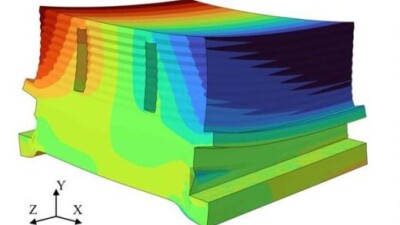

Additive manufacturing, sometimes called 3D printing, isn’t what you think it is. For part making with extreme complexity and impossible to fabricate features like enclosed volumes, it’s unequaled, and surprisingly to many, it’s been around for decades. Why does it feel so new? Mainly because the technology of additive is still evolving, with multiple, radically different operating principles, each with advantages and disadvantages. Whatever the technology, additive is now legitimate mass production tool, and aligning machine capability, heart costing and return on investment is critical.

Joining engineering.com on this episode of The Engineering Roundtable are four experts to discuss advanced additive as a production tool as well as the financial considerations when adopting additive for volume production:

Panelists:

Jeff Blank, Co-Founder & COO, Evolve Additive Solutions

Hugh Evans, Founder and Managing Member, 3D Ventures

Jesse Marin, Additive Technology Center Manager, Fathom Digital Manufacturing

Matt Buisker, Senior Research and Development Engineer, Daktronics

Moderator:

Jim Anderton, Multimedia Content Director, engineering.com

* * *

Learn more about Evolve Additive Solutions’ electrophotographic (EP) imaging and deposition technology.