Speed and agility have become critical in the delivery of new therapies, devices and drugs.

Siemens has sponsored this post.

Written by: Dale Tutt and Jim Thompson, Siemens Digital Industries Software

The medical device and pharmaceutical industries are emerging from a period of unprecedented challenge and upheaval. Supply chain challenges and growing complexity have impacted the industry at a time when speed and agility have become critical in the delivery of new therapies, devices and drugs. Meanwhile, the management of risk and protection of patient safety and privacy have remained paramount despite shortening timelines.

This disruption, however, has sparked a wave of innovation and ingenuity in the design and production of medical devices and pharmaceuticals. The addition of digital elements, electronics and software to the life sciences industry has powered the creation of smarter and cheaper medical devices and accelerated the development of new drugs. The ongoing digitalization in the delivery of healthcare is also laying the foundation for a shift in how care is delivered, where home is becoming the new hospital.

Medical device and pharmaceutical trends in the post-pandemic era

The pandemic highlighted the significant built-in risk associated with highly global supply chains; which had become the norm across industries. The pandemic also prioritized condensing already shrinking development cycles. Disruptions to semiconductor production also hampered the production of various devices, vehicles and equipment. This impacted nearly every industry as computing and electronics approach ubiquity.

Meanwhile, the rapid development of the COVID diagnostic tests and vaccines demonstrated to the industry that faster timelines can be achieved within the current regulatory framework, catalyzing device manufacturers and pharmaceutical companies to search for better means of managing the complexities of drug and device development to minimize development cycles.

Shifting care from hospital to home

Methods of delivering care have also undergone some upheaval in recent years. Hospital beds are in high demand as many populations age and require increased care. With limited space and growing costs in traditional hospital and clinical settings, the ability to deliver high quality care remotely and to support patients outside the confines of the hospital is becoming crucial.

This requires increasingly intelligent, robust and safe medical devices that can be distributed to patients for use in their homes or on the go. For device manufacturers, the result is increased complexity in the design, engineering and regulatory clearance of new devices to ensure safety, efficacy and ease-of-use by untrained users. For example, smart glucose monitors are now available that can be worn or implanted, helping diabetes patients manage their condition more easily and reduce episodic emergency clinical care. The smart device continuously monitors blood glucose levels, displaying this information for the patient to use in tracking their blood sugar and its responses to diet, exercise, stress and other factors.

The age of software-defined care

Software is an increasingly central piece of the delivery of modern therapies, and this will only heighten in the future. Software is everywhere in life sciences and healthcare. It is used in the design, production, operations, delivery and management of devices and drugs. Software is also being used increasingly as a medical device itself. The integration of software into such a multitude of processes has enabled remarkable advancements in the technology of medicine, aiding in the diagnosis and treatment of disease, the management of chronic conditions and the organization and security of patient data. Yet, the growing application of software and digitalization in the medical space incurs some challenges.

All this software, including updates whether used by a medical provider or by a patient, must undergo rigorous certification and risk assessment to ensure patient safety and efficacy. Furthermore, smart medical devices, software as a medical device and even wellness devices such as a smart watch all produce or manage highly sensitive patient data. Manufacturers must therefore adopt rigorous data security and risk management protocols with the same attention and investment paid to traditional innovation pathways for medical products and therapies.

Digitalization fosters improvement and innovation

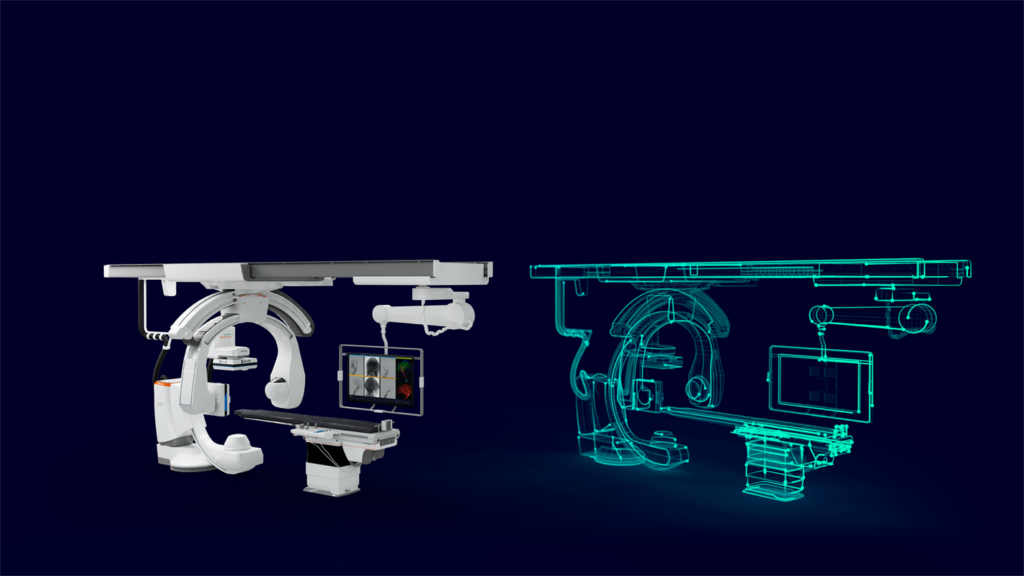

Digitalization and digital twins are being adopted by the medical industry for their ability to improve underlying engineering, design and data management processes. This becomes particularly important as devices become more complex, smart and software-defined. Medical devices are an especially good fit for advancing the digitalization of design, engineering, testing and production as many are discrete-manufactured products, created in the same way as cars or smartphones — two examples of industries that are viewed as leaders in digitalization. The comprehensive digital twin of a new medical device enables engineers to simulate and predict multiple aspects of device performance, such as heating or power consumption, to ensure reliability and safety. Likewise, digitalization is a boon to the development of surgical robotics that are highly precise and robust, enabling surgeons to perform delicate tasks with confidence.

Due to the potential advantages digital twins can offer, digitalization is top of mind for medical device and pharmaceutical companies. Yet, the necessity for safety and minimizing risks, and the high regulatory standards with which new devices and drugs must comply, have prevented these industries from embracing digitalization on the same timeline as others, such as the automotive and consumer electronics industries. For manufacturers of medical devices and drugs, the potential benefits of a new technology or methodology must be sufficiently evaluated and proven to displace a legacy process due to the importance of preserving product quality and patient safety.

So, looking to the future, how can engineers and designers expect digitalization and the digital twin to advance in the medical device and pharmaceutical industries to further adoption?

The evolution of digitalization in the delivery of new therapies

Broadly, continued investment in digitalization will open new opportunities for the application of the digital twin, automation, artificial intelligence (AI) and the industrial metaverse with respect to the development of medical devices, implants and pharmaceuticals. The application of these technologies will be crucial for increasing the productivity of healthcare systems and improving the remote delivery of care. As space in hospitals becomes increasingly limited, especially for aging populations, the ability to provide effective care whether in the hospital or at the home will be vital.

The pharmaceutical industry is already taking advantage of AI to analyze drug performance to better understand how the body absorbs different medications. The regulatory approval of a new pharmaceutical requires multiple stages of testing in both laboratory and clinical settings. These trials typically produce large data sets on the drug’s efficacy, side effects, risks and patient data. AI is being used to examine extremely large data sets, looking at biomarkers to characterize the complex interactions between individual anatomy, genetics and the chemistry of the drug being administered. By considering results from multiple studies involving several drugs, biologists and physicians can use the power of AI to uncover interactions that may not be obvious in any individual study, resulting in drugs that are safer and more effective.

Looking further into the future, the industrial metaverse may be applied to the delivery of healthcare to reduce the time patients spend in care facilities, costs and improve condition diagnosis. A typical doctor visit may transition to a remote consultation in which the physician can examine a digital twin of some part of the patient’s anatomy, helping both the provider and patient better understand the patient’s specific disease and treatment options.

Furthermore, the work already being done with AI and pharmaceutical development may enable physicians to customize a drug or therapy to the patient’s anatomy, genetics and condition, accentuating health benefits and mitigating side effects. Routine wellness visits may also be more effective at catching conditions early, preventing lengthy and expensive hospital stays and improving patient outcomes.

A digital future for medical devices and pharmaceuticals

As medical device and pharmaceutical manufacturers emerge from a disruptive and uniquely challenging period, they face a future of growing complexity, speed and innovation. Medical device makers are managing the development of devices that are smarter, increasingly complex and more user friendly. This places additional strain on traditional design and engineering methods. Meanwhile, the need for speed of innovation in both device and pharmaceutical spaces has elevated, driving manufacturers to seek process improvements that can accelerate development cycles while preserving safety, efficacy and data security.

Digitalization and the digital twin are relatively nascent in the medical device and pharmaceutical industries. Yet, with a commitment to digitalization and the application of powerful technologies like the digital twin, AI and the industrial metaverse, manufacturers of medical devices and pharmaceuticals can build a foundation for transformative capabilities that will enable them to develop new generations of devices and therapeutic drugs. These advanced therapies will contribute to a system of care that is more productive, accessible and effective.

About the Authors

Dale Tutt is Vice President of Industry Strategy at Siemens Digital Industries Software. Dale leads a team of experts to develop and execute industry-specific product and marketing strategies in collaboration with the global product, sales, and business development teams. With over 5 years of experience in this role, combined with extensive experience in the aerospace and defense industry, Dale has a deep understanding of the challenges and opportunities facing companies as they embark on their digital transformation journeys. Connect with Dale on LinkedIn.

Jim Thompson is the Senior Director of Digital Strategy for the Medical Device and Pharmaceutical Industries at Siemens Digital Industries Software. Jim has three decades of experience in product lifecycle management and solutions development. His current role focuses on strategy and solution management for the Medical Device and Pharmaceutical industries. Connect with Jim on LinkedIn.