What GPU is right for you? How much RAM is enough? How do you futureproof your desktop workstation? Here’s everything to know when configuring a computer for CAD, CAM, simulation and more.

The greatest computational tool engineers have is their brain. The second greatest is their workstation.

You can’t choose the computer in your cranium, but you can choose the one on your desk. That choice will impact how effectively any engineer can do their job, so it’s worth taking the time to consider it properly.

Need some help? We asked industry insiders for their best advice on configuring engineering desktops. From understanding your workflow style to picking the perfect processors, here’s everything you need to know when buying your next engineering computer. (Though this advice is tailored to desktops, it’s generally relevant to engineering laptops as well.)

The two main types of workstation workflows

Every engineer’s job is unique, and so is their desktop workstation. The first and most important step in choosing your computer is to determine how you plan to use it.

Are you an interactive or computational user? These are the two main types of engineering workflows, according to Scott Hamilton, global industry strategist for engineering and manufacturing at Dell. Interactive workflows involve a real-time exchange between user and system, such as a CAD designer orbiting a 3D model. In this workflow, the computer serves as a live canvas. In contrast, computational workflows happen more in the background — a user sets up a problem and the computer crunches the numbers. Think of an analyst running a computational fluid dynamics (CFD) simulation or an engineer training a machine learning model.

Each type of workflow requires a few key workstation specs, and understanding the differences between them will help you make the most of your hardware budget.

Interactive workflows: How to configure a CAD computer

Interactive workflows are often single-threaded or lightly threaded, meaning that the central processing unit (CPU) can’t distribute the workload across all of its cores. For these types of workflows, it’s much more important to have a CPU with a high clock speed as opposed to a high core count.

“The highest possible clock speed will deliver the best performance for solid modeling applications like Dassault Systèmes Solidworks and Catia, PTC Creo, Siemens NX, [and] Autodesk Inventor,” Chris Ruffo, Lenovo’s worldwide segment lead for AEC and product development of workstations, told engineering.com. Ruffo suggests that the latest Intel Core i9K processors can provide the necessary speeds (at time of writing, the fastest of these is the Intel Core i9 14900K with a top speed of 6GHz.)

Since responsive visuals are required in interactive workflows, it’s also crucial to have a graphics processing unit (GPU) with strong rendering performance and high memory speed. A more expensive graphics card doesn’t necessarily mean better rendering performance. Modern GPUs include cores not just for rendering graphics, but also increasingly for other types of computation such as machine learning.

“For those engaged in design and visualization workflows,” Ruffo says, “an Nvidia RTX 4000 Ada Generation graphics card offers superior performance for real-time visualization, virtual reality and mixed reality workloads.” Dell’s Scott Hamilton makes the same graphics card recommendation, and also points to more cost-effective options, like the Nvidia RTX A2000 12GB, as a reasonable option for most CAD users.

Computational workflows: How to configure a desktop for simulation and CAM

Computational workflows are often multi-threaded, so it’s crucial to pick a CPU with a high core count. Since each core can contribute to the calculation, every extra core can bring down the total solve time. And with those cores churning through lots of data, it’s important to choose a CPU with a high amount of on-chip memory — so look for processors with a large L3 cache size.

Ruffo suggests the Intel Xeon W series and AMD Ryzen Threadripper Pro 7000 WX series of processors are well suited to computational workflows including computer-aided engineering (CAE) and computer-aided manufacturing (CAM). “Solutions like Ansys and Siemens Simcenter STAR-CCM+ have solvers that leverage high core counts — in some cases up to 64 cores or more,” Ruffo says.

Likewise, computational workflows benefit from a GPU with strong computational performance and high memory capacity. “Graphics are not just for visualization!” Ruffo says. “Many CAE simulation solutions like Dassault Systèmes Simulia and Ansys Discovery Live utilize GPU compute to accelerate performance for multi-physics workloads and take advantage of higher-preforming GPUs like the Nvidia RTX 6000 Ada Generation graphics board.”

Configuring the best computer for your needs

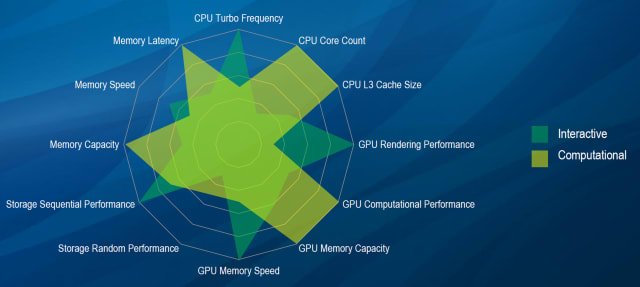

If your workflow doesn’t fit cleanly into one of these categories, don’t worry — most engineers’ workflows don’t. But they can still serve as a helpful guide when configuring your workstation. If you spend most of your time in CAD programs like Solidworks or frequently use virtual reality (VR), lean towards an interactive-focused workstation. If you rarely need real-time visualization, tune your specs towards a computational workflow. And if you have an even split, look for the most cost-effective way to balance the specs for both workflows. Hamilton provided this handy radar chart to help out:

Whatever your workflow, you’ll want plenty of system memory. How much RAM is enough for engineers? Ruffo recommends a bare minimum of 32GB, adding that for many CAD users, 64GB is becoming the norm. For workflows involving large visualizations or simulation workloads, Ruffo says 128GB of RAM will prove useful. In general, the more data you work with, the more memory you need.

Futureproofing your desktop workstation

There’s one more wrinkle to keep in mind when configuring your workstation—time. The average system life of an engineering workstation is three years, according to Hamilton, so do your future self a favor and buy a system that will serve your needs as they evolve.

Take the graphics card. Even if you don’t expect your graphics needs to change over the next few years, your engineering software will continue to add features that leverage the GPU — particularly AI features that use its machine learning cores. “In general, I would say go up a level in graphics performance,” Hamilton says, meaning users should find the right graphics card for their present needs and buy the next step above it in performance (for instance, going from the Nvidia RTX 4000 Ada to the RTX 4500 Ada).

It’s not just about buying the specs for your future self, but also about buying the flexibility to upgrade as needed. If you anticipate an increasingly graphics-heavy workflow, ensure you have room (and power) to add a second graphics card if and when you need it. Memory, too, can be easily upgraded — but only if you plan ahead. If your workstation has four memory slots and you want 32GB of RAM, configuring it with four 8GB DIMMs would take up all your channels. Instead, two 16GB DIMMs would leave two memory slots open, making it easier for you to upgrade to 64GB of memory later.

How much should you spend on an engineering computer?

Every engineer will benefit from having the right workstation for his or her needs. Though it’s possible to buy an entry-level engineering desktop for not much more than a thousand dollars, as you spec it to your requirements the price can fly into the tens of thousands of dollars (especially for computational workflows). Of course, you should spend within your budget. But keep in mind that while the cost of engineering computers can be high, the cost of engineers using subpar computers can be even greater.

“Don’t buy a super high end stereo system and put cheap speakers on it,” Hamilton says. The cost of an engineer is far greater than the cost of their workstation, and equipping engineers with a sufficiently powerful workstation will allow them to work at their full capacity. If they can eke out even 10% more productivity with a properly configured workstation — as opposed to one less suited to their workflow — the cost of the proper workstation justifies itself.

“The other thing you’ve got to consider is what I would call the more intangible benefits,” Hamilton says. “What if you can design the product faster, beat your competition to market, or build a better product that has more quality?” The right computer in the right hands, he argues, confers these benefits.

It’s worth reiterating that the right workstation will look different for every engineer. Some will be optimized for interactive workflows like CAD and AR/VR, others will be better suited to computational workflows like simulation, CAM, and AI. By understanding your needs — now and in the future — you’ll be able to choose a computer that helps you be the best engineer you can be. If only it was as easy to configure your brain!