MMSLA introduces innovative technologies to overcome key challenges in AM.

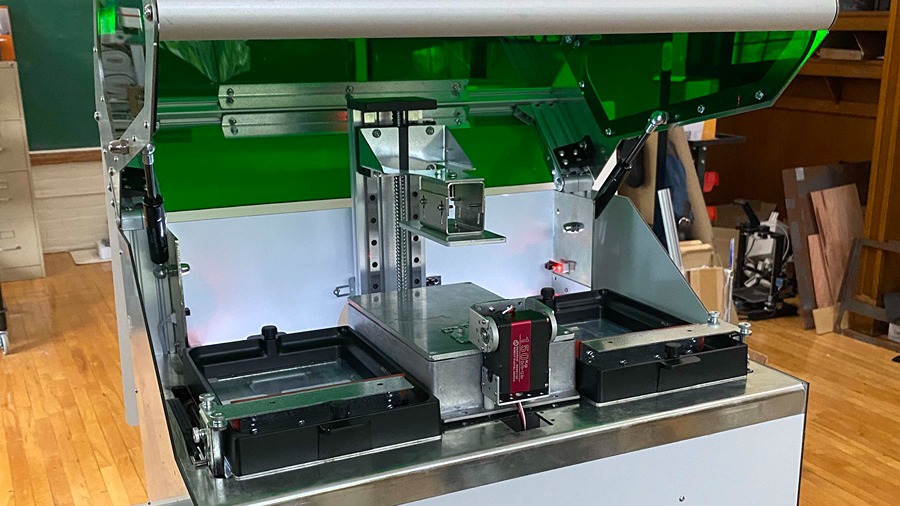

NASHUA, NH, Nov 18, 2024 – MAASS announced the sale of their Shimmy MMSLA (multi-material stereolithography) 3D printer, marking their transition from internal development to a commercial product by introducing a groundbreaking platform for multi-material additive manufacturing research and development.

“Huge strides have been made in resin printing, but absolutely nothing for printing with more than just one” said JF Brandon, CEO of MAASS. “The Shimmy MMSLA represents that shift by enabling unprecedented control over multiple materials at the microscale, opening new possibilities for integrated electronics, smart materials, and next-generation manufacturing processes.”

Breakthrough Multi-Material Technology

MMSLA introduces several technological innovations that address long-standing challenges in additive manufacturing:

- Dual-vat system enabling simultaneous printing of two distinct materials

- Resolution capabilities ranging from 0.5 to 50 microns

- Integrated cleaning system that prevents cross-contamination between materials

- Support for high-conductivity and dissolvable support materials

- Build volume of 78mm x 51mm x 141mm optimized for R&D applications

Enabling Next-Generation Applications

The system’s unique capabilities make it particularly valuable for several emerging applications:

- 3D printed electronics with 2-mil (50 micron) conductive traces

- Complex non-planar circuit designs

- Dissolvable support structures for ultra-high-quality surface finishes

- Research and development of smart materials

- Rapid prototyping of multi-functional devices

Strategic Focus on R&D and Future Manufacturing

While the initial release targets the research and development market, MAASS’s technology platform is designed to scale for future manufacturing applications. The company’s roadmap includes developing higher-throughput systems based on the same core technology for mass production of multi-material parts.

A Winning Team

MAASS was developed internally by Nectar Labs, a boutique Research and Design lab. JF Brandon is a partner at Nectar with Nicholas Coluccino, and together led the team from concept to reality in less than 18 months. Nectar has developed software and hardware products for major entities like Forest Stewardship Council and Heifer International. JF Brandon is an accomplished entrepreneur in the additive manufacturing space. Brandon’s track record includes key roles in successful ventures like GrabCAD and BotFactory, and his innovations have been recognized through major awards including the $50,000 Change the Course Competition and special mention from Autodesk/Future of Manufacturing.

For more information, visit maass3d.com.