A 5-year plan aims to have robots compensate for the country’s decreasing workforce.

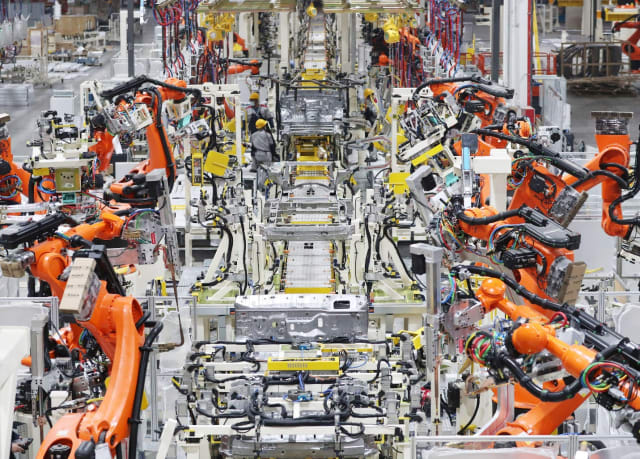

It may be comforting for American industry to think that it has a technological lead in manufacturing, even if the bulk of manufacturing is being done offshore. Of course, the U.S. has the most advanced manufacturing—the automation, the precision and industrial robots. We think of lights-out factories, with automated assembly lines, assembly-line robots amid a shower of sparks doing spot welding and driverless material handlers. If a soul would be in sight in such a setting, they would doubtless be American. We think of computerized assembly and manufacturing as a birthright—our superiority in AI and innovation, a force multiplier. Why, one our robots can do the work of a hundred foreign laborers, right?

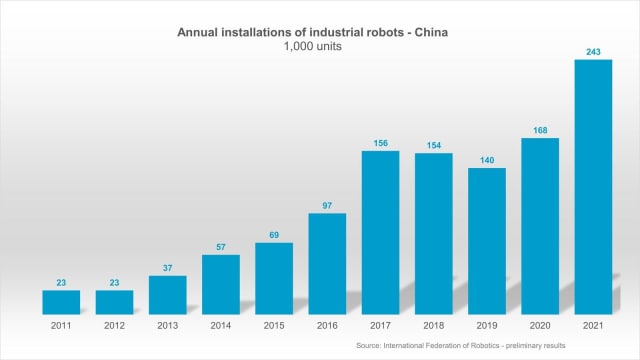

It will be a shocker to read the recent report from the IFR, the International Federation of Robotics, which reveals that China now has almost half of all the world’s robot installations and that it is increasing its lead rapidly. The IFR, which exists to “promote research, development, use and international co-operation in the entire field of robotics,” has been reporting that China has been the world leader in implementing industrial robots for the last 8 years. We have not been paying attention. In 3 years, China has almost doubled the number of industrial robot installations. With its 243,000 robot installations in 2020, China has almost half of all the industrial robots in the world, according to the Wall Street Journal.

Germany, the country where Industry 4.0 originated and where the IFR was established in 1987, may well have been expecting to report on its lead in industry robots, only to have China steal the show.

A majority of new industrial robots are used in electronics manufacture (for circuit boards, consumer electronics, etc.) and in automobile assembly, particularly in the surging production of electric vehicles (EVs).

One must wonder why China, a country with so much cheap manual labor available, would opt for expensive robots with their special demands for tech support. China may have a giant population (1.4 billion people), but its workforce is actually decreasing, says the IFR, due to an increasing segment of its population aging and a growing competition for service jobs. China also expects a leveling off of its rural-to-urban migration.

China’s government is determined not to let a declining workforce cause a drop in manufacturing, and as only a centralized, authoritarian government can, it has made robotizing a national priority and has mobilized its forces.

China’s latest five-year plan for the robotics industry, released in December 2021 by the Ministry of Industry and Information Technology (MIIT), aims for nothing less than making China a world leader in robot technology and industrial automation.

And it appears to be working. China went from 10 robots per ten thousand employees 10 years ago to 246 robots per ten thousand employees in 2020, the ninth best ranking in the world.

To keep the robots state of the art and operational, China’s Ministry of Human Resources and Social Security introduced 18 new occupational titles in June, including “robotics engineering technician.”