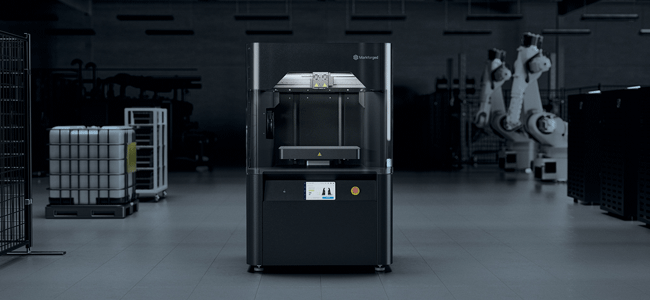

Additive manufacturing (AM) carries unique benefits compared to traditional manufacturing.

Production of everything from prototypes to end-use parts is faster, cheaper, easier to use, and more accessible than subtractive manufacturing methods — which are more complicated and expensive to operate. Investing in additive manufacturing can greatly improve efficiency and agility while minimizing supply chain risk, while its automated processes reduce the need for specialized labor. 3D printing is also efficient: you build only what you need to, and nothing more.

Additive manufacturing has seen widespread use due to these benefits. 3D printing technologies have continued to move forward and several key advancements have been made in recent years. Today, AM solutions are more reliable and effective than ever before. They have a wider range of capabilities and potential applications, and can print parts that address specialized needs.

So, what are these improvements, how do they translate into concrete benefits for manufacturers, and why is now the time for businesses to invest in additive manufacturing? Read this white paper to learn directly from resident engineers and technical experts at Markforged.

Your download is sponsored by Markforged.