ECE’s new analog design course offers TI's expertise through lectures, mentorships, and tech access.

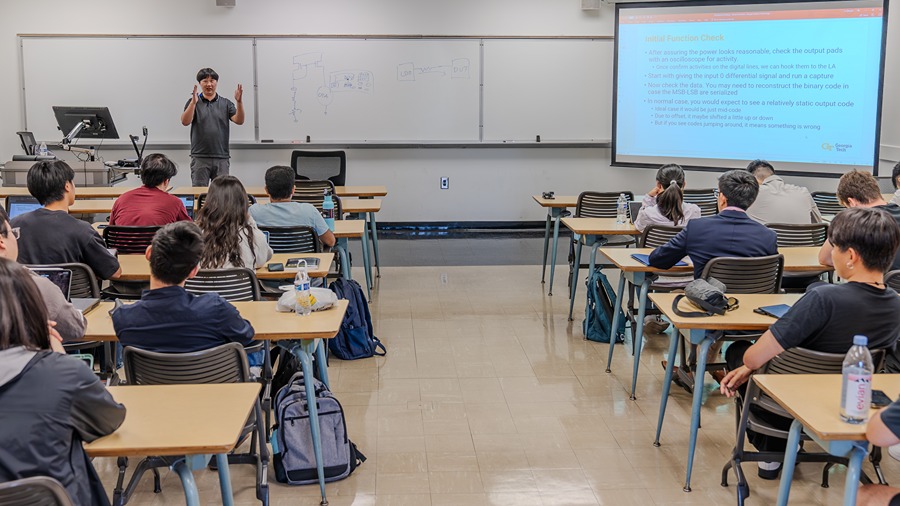

Georgia Tech’s School of Electrical and Computer Engineering (ECE) is working with Texas Instruments (TI) to launch new classes where students have direct access to industry-grade analog chip design, fabrication, and testing processes. ECE’s analog and mixed-signal design curriculum now features a new course where students can benefit from TI’s expertise — through guest lectures, mentorships, and this technology access. We spoke with Assistant Professor Shaolan Li about this new way forward for circuit design education.

Li has worked for ECE for the past five years. Before his professorship, he earned his bachelor’s degree at Hong Kong University of Science and Technology. He then moved to the U.S., where he obtained his PhD at the University of Texas at Austin in 2018, and then he spent one more year working as a postdoc at UT-Austin.

Li’s teaching interests focus on analog and mixed-signal circuits, something that he says developed around the second or third year of his bachelor’s degree, when he studied abroad at UCLA.

“I was drawn to the beauty of analog circuits for the first time while in an analog circuits class,” he said. “There’s a lot of things to learn, but eventually I became relatively adept at it. I also wanted to do research on analog circuits, because there are a lot of unsolved problems with them, in my opinion.”

Engineering.com: What inspired the collaboration between Georgia Tech and Texas Instruments?

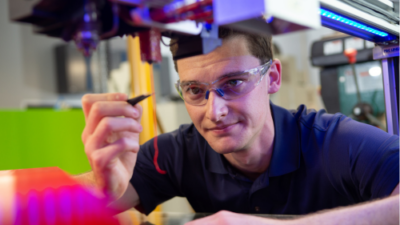

Li: Analog circuit design is a very traditional course that started more than 100 years ago. The problem with the conventional program was the lack of hands-on practice for the students. When you built analog circuits on boards in the old days, you were able to play around with the soldering components on a PCB and take measurements with an oscilloscope, spectrum analyzer, etc.

But as you know, technology is advancing. These days, almost all of the university classes involve building integrated circuits. When it comes to integrated circuits, however, hands-on education is a lot harder because you have to find a way to fabricate the silicon and then measure it correctly. The silicon is the biggest problem because you have to work with a foundry. There are concerns with that, the first of which is cost. It is very expensive to fabricate an integrated circuit. The other concern is typically associated with the legal side, which involves going through a complicated legal negotiation in order to set up the fabrication process.

I would say that for the past 30 or 40 years, most analog IC education results in simulations. It’s more like a toy; a model of transistors, using simulators like SPICE or Spectra. They get a sense of how to design things on the computer and simulate it, but they don’t really get the chance on touching the real things and measuring them.

Yet here’s a gap. When you have students learn by way of simulation, they think the end result is good. But they are missing a lot of the real-world effects, the non-idealities, that occur when they are on the physical silicon. When they graduate and go to work, it takes a longer time for them to adapt to the real-world design environment. We really want to bridge this gap and make like an analog IC education more realistic for the students and allow them to gain practical design experience.

Engineering.com: What is the significance of analog circuits in established technologies, as well as any emerging technologies?

Li: Analog circuits are everywhere and yet, these days, we talk about how powerful digital computers are. The thing is there are almost always some sort of analog parts inside a digital chip. For example, they may regulate the power supply of the digital chip. They may manage how much current should be delivered. We also have a lot of sensors that could be measuring the temperature of the CPU, whether a certain part is going to be too hot, or whether to redistribute the workload to another place.

There are also really high precision analog applications that are used to sense the real-world information, such as human body vitals or a very small signal coming from space. Whenever you want to send something from the environment, you have to use analog circuits.

You also have analog circuits used in communications, such as in your cell phone, where you want to receive, or you want to send out information. To do this, you have to go through the power amplifiers and then through the receiver chain. And those are analog circuits. In between the analog world and the digital world, you also have to translate analog information into ones and zeroes.

Looking into the future, have we already built enough analog circuits to sustain future applications? The answer is no! A lot of the emerging applications still require analog circuits and more and more powerful ones, too, such as those required for artificial intelligence. Artificial intelligence systems will eventually need to interact with the environment. To do that, you will need an interface between the AI accelerator or computing device and the environment. That interface requires analog circuitry.

With quantum computing you will need to rely on analog to control the core of the quantum computer — the qubit. That is done by first modulating the signal into an analog frequency waveform. They are not controlled by digital actually, they need to modulate the signal first into an analog kind of radio frequency waveform. So, analog circuits are everywhere, and their importance will continue to grow. It’s a very essential circuit in our lives.

Engineering.com: What challenges do students face when they’re learning the chip tapeout process in classes?

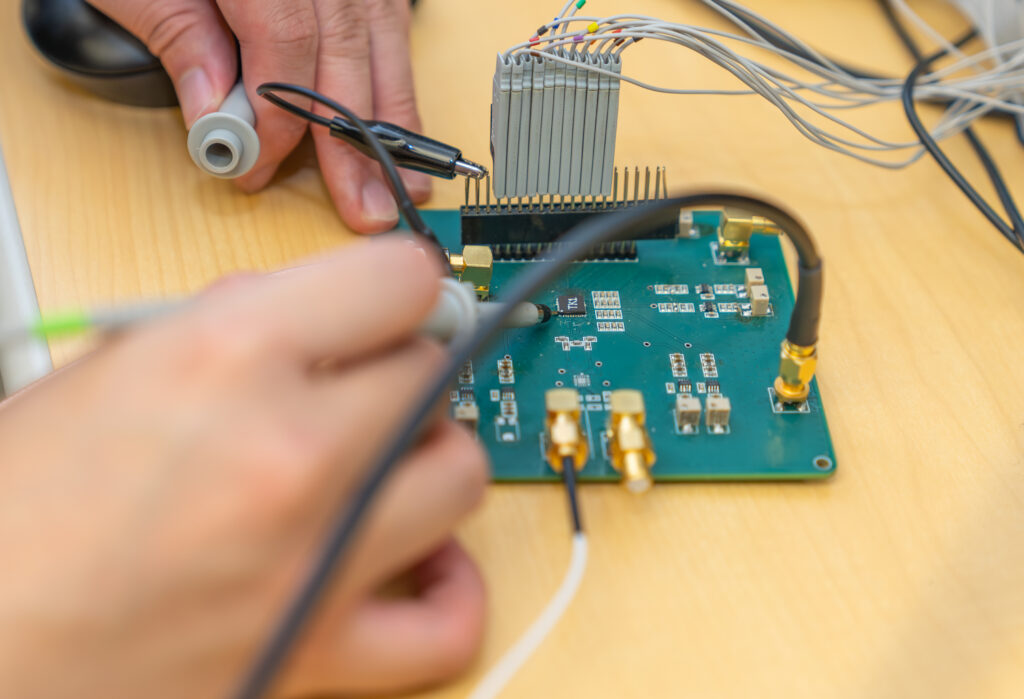

Li: Tapeout is essentially the process of bringing your idea into a design, and then turning the design into a fabricatable mask. Then, you send the mask to the foundry, which guides the foundry on how you want to grow the silicon on the wafer. This is an absolutely essential process for the success of the design. There are actually a lot of challenges throughout the whole tapeout process for students, especially for someone who has a very limited experience in circuit design.

The first challenge they may have to meet is taking the specification that the customer provided to them and translating those specs to a circuit — choosing the right architecture and circuit topology.

After that, they have to draw the circuit on their own — not drawing the symbol or schematic, but actually drawing the layout of how the chip should be arranged on the piece of silicon. The layout process is new to almost all the students that are taking my class. It takes them a while to figure out what each layer means and how to picture the 3D structure of the layers in their mind. There is a learning curve.

The third challenge is how to minimize the post layout degradation of the circuit performance. When you start to do the layout and then simulate a circuit, there are suddenly a lot of non-ideality associated with the placement of the different layers and this can start to affect the circuit performance. These non-idealities include like plastic capacitance, IR drop, or a systematic or random mismatch. Then they have to figure out a good way to kind to overcome this and adjust their layout.

Then the fourth and final challenge involves the preparing to send the chip for tapeout. They have to put everything they designed together and pass what we call the design rule check and the layout-versus-schematic rule check. This process helps to ensure that the design is in compliance with the manufacturing requirement and that there’s no major mismatch between what you intend to design and what you actually drew.

Engineering.com: What kinds of student feedback have you gotten regarding this experience?

Li: They say, it’s very intensive, but it’s very rewarding because they learn a lot during this class. The students who have to go through this paper process on their own gain a lot more insights compared to students who only like play with the simulations. This experience can give them better understanding of how an analog circuit works in the real world. As we analog designer always say, insight or intuitions are the most important components in this subject. So, I think this experience better prepares them a designer job when they join the industry.

Engineering.com: How unique is this program of type of program? How does this position Georgia Tech in this area?

Li: In my opinion, Georgia Tech’s program is very unique. It’s probably the first program in the U.S. in terms of providing a tapeout opportunity to undergraduate students. It may not be the first one to provide a tape out opportunity for graduate students. From what I know, Universities such as UCLA and Columbia already have a tapeout program for their graduate students. But it’s only for a very small batch of students. They don’t really have the same scale as what we do here at Georgia Tech for undergrad students, not to mention for a large number of students.