Though they don’t match lithium-ion on energy density, OIBs have one huge advantage for large energy storage applications.

Researchers from the Vienna University of Technology have discovered an interesting new battery technology: the oxygen-ion battery (OIB) based on ceramic materials. Its most attractive feature is an ability to regenerate itself with ambient oxygen, which provides the potential for an extremely long service life.

Detailed in a January 2023 paper in Advanced Energy Materials, the novel battery concept has already been patented, paving the way for an appearance in the real industry sector. However, oxygen-ion technology will probably not beat the current kingpin, lithium-ion, in all applications. It does not have as high an energy density as Li-ion batteries, but it does have numerous advantages, especially for one important application: large energy storage systems (ESSs) such as renewable energy sources, power grids, microgrids and more.

The ceramic advantage

Ceramic is the key to the new oxygen-ion batteries. The Vienna University of Technology researchers developed ceramic materials that can absorb and release doubly negatively charged oxygen ions, so the oxygen ions can migrate from one to another ceramic material. Ceramic materials are the key components in OIBs and provide ionic conductivity, stability and durability for the battery.

The battery prototype uses lanthanum, which is not widely available and is still expensive. However, lanthanum can be easily replaced with cheaper and more widely available materials, and the researchers are already working on doing so. Better yet, the expensive elements cobalt and nickel, common in today’s lithium-ion batteries, are not used at all.

“In this respect, the use of ceramic materials is a great advantage because they can be adapted very well. You can replace certain elements that are difficult to obtain with others relatively easily,” said researcher Tobias Huber in a Vienna University of Technology news release.

How oxygen-ion batteries work

Oxygen-ion batteries work similarly to lithium-ion batteries. Like Li-ion batteries, where lithium is incorporated in electrodes, neutral oxygen can be incorporated in OIBs by annihilating oxygen vacancies and creating electron holes.

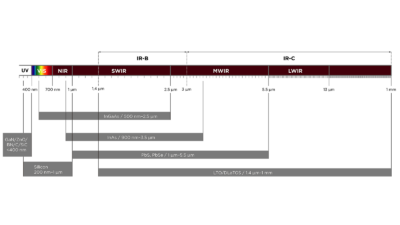

The electrodes of OIBs are composed of a ceramic material with a high oxygen affinity, such as perovskite-type oxides. Mixed conducting oxide electrodes can change stoichiometry (depending on the oxygen chemical potential), and thus absorb and release oxygen ions during the battery charging and discharging process. For this purpose, MIEC oxides (mixed ionic electronic conducting perovskite-type oxides) are used to create thin film electrodes with blocked oxygen surface exchange. The researchers investigated different variations of electrodes, such as LSM, LSCF and BSCF. These have the ability to conduct both electrons and ions, and oxygen can be incorporated or evolve on the entire electrode surface.

The oxygen-ion battery’s solid state electrolyte uses a ceramic material with high oxygen ion conductivity, enabling the migration of oxygen ions between the cathode and anode while preventing electronic conduction. The researchers used yttria-stabilized zirconia (YSZ) single-crystal electrolytes. The zirconia layer is constructed for oxygen blocking.

The prototype battery demonstrated good cycling performance, with less than 1% of the charge being lost per cycle. The tested cells had a 0.6V cell voltage, so future optimization of OIBs could see a higher cell voltage, perhaps using different electrode materials.

OIB benefits and future improvements

Ceramic material is a good step away from the rare, non-environmentally friendly materials used in most batteries today. It is also not flammable, which solves the biggest issue of Li-ion batteries: fires. Solid-state ceramic electrolytes pose no risk for leakage or thermal runaway and enable more compact and flexible battery configurations and designs.

The most prominent advantage of OIB is its long life span. Most of the available battery technologies lose their capacity after many charging cycles. When oxygen is lost due to side effects, OIB can be regenerated with ambient oxygen.

However, there are still challenges to overcome before OIBs will work in the real world.

OIB batteries do not have ideal properties, and they will probably not be the best choice for all applications. Their energy density is significantly lower than Li-ion batteries, which deters wide use in small electronic devices such as smartphones, or in electric vehicles (EVs), especially as their operating temperature is between 200 and 400 °C. There is room to improve oxygen-ion conductivity by developing high-performance ceramic electrolytes. However, high-performance ceramic materials should have reasonable prices that can be achieved by optimizing material synthesis processes and reducing production costs.

Nonetheless, OIBs are still very interesting in ESS applications such as storing solar and wind energy, where space and temperature do not play a key role. OIBs can provide long service life and could be produced in large quantities due to their widely available materials. This novel battery may also prove useful for applications requiring elevated operating temperatures, for which common cation-based cells are not applicable so far.