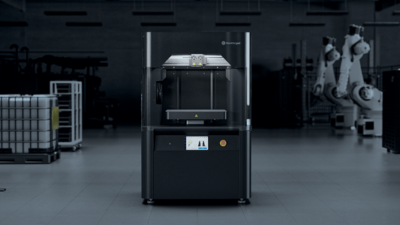

The adoption of data-driven methods is a key factor in advancing AEC and catching up to manufacturing. Use of digital technology will modernize an AEC firm and allow it to address their needs for improved project hand-off, increased sustainability, and streamlined operations.

While manufacturing quickly caught onto the benefits of a digital transformation, AEC, especially construction, has been left behind. This has led to slow adoption of technology that has been proven to increase efficiency, save time and keep costs down.

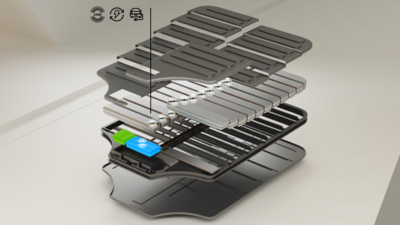

The adoption of data-driven methods is a key factor in advancing AEC and catching up to manufacturing, an industry that maximizes digital tools, including digital twins, to maximum effect. This is most apparent in the way AEC projects are all one-off and manufacturing has embraced mass production.

The use of digital technology will modernize an AEC firm and allow it to address their needs as well as their customers with:

- Improved project hand-off

- Increased sustainability

- Streamlined operations

Download this white paper and you will learn how digital tools and digital twin can address challenges in AEC, including:

- Product complexity

- Labor shortages

- Supply chain issues

- Waste of materials and resources

- Converting to mass production method, in part if not whole (as with prefabrication)

- Using PDM and PLM to help with reuse of designs from one project to the next

Your download is sponsored by KitConnect.