Considering how easy it is to automate spot welding, it has historically been the most common joining process for high-volume manufacturing industries, such as the automotive industry. Learn to become more efficient in the assessment of spot weld quality while at the same time improve the predictiveness of crash safety simulations.

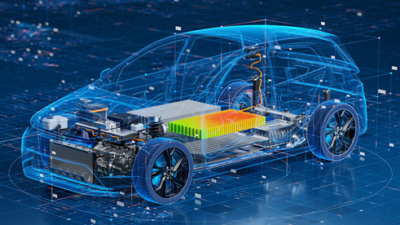

Automated spot welding is the primary joining method in high-volume manufacturing like the automotive industry. With a typical car containing over 3,000 spot welds of various types of alloys, steels and galvanized sheets, OEMs must accurately predict their strength early on so they can ensure structural integrity, safety and prevent costly setbacks in later stages.

Given that the amount of spot weld combinations can easily exceed 1 million, it is therefore not realistic to assess the quality and joining strength of each individual spot as it would be too costly and time-consuming.

To predict their robustness accurately and enhance vehicle integrity, ESI Group has developed a virtual solution that can help you improve your assessment of spot weld quality as well as the predictiveness of crash safety simulations.

Watch this webinar and learn how to:

- Control and optimize spot weld process virtually to ensure required weld characteristics

- Easily check robustness of the welding process through a weld lobe diagram

- Integrate the welding history in virtual coupon rupture tests for more accurate prediction of force-displacement curves

About the Speakers:

Mark Vrolijk – Sr. Solutions Analyst, Product Management & Marketing – ESI Group

Mark Vrolijk holds a master’s degree in Aerospace Engineering from the Technical University of Delft, Netherlands. He began his career as a technical researcher at the university, focusing on aerospace manufacturing process enhancements. Later, Mark joined ESI, starting as a technical support engineer, gradually specializing in sheet metal forming. Over a decade, he took on various roles, including validating ESI’s die face design solution and serving as technical product manager.

Mark transitioned to product marketing for PAM-STAMP. During this time, he actively engaged with customers, presented at conferences, and authored papers, particularly in the field of hot forming. His journey at ESI also encompassed roles as a business development manager and strategy manager for sheet metal forming solutions. Currently, Mark spearheads the product marketing efforts for ESI’s comprehensive virtual manufacturing portfolio, spanning stamping, casting, composites, welding, and assembly.

Simon Dussinger – Technical Team Lead – ESI Group

Simon Dussinger is a Civil Engineer with a specialization in structural engineering, holding a degree from the renowned Karlsruhe Institute of Technology (KIT). His journey with ESI began in 2009 when he joined as a CAE Application Engineer VPS. Over the years, Simon’s dedication and expertise were acknowledged, leading to a well-deserved promotion in 2020 when he assumed the role of Team Leader for Crash, Safety, Static, and Dynamics.

With an innate ability to harness the power of simulation and virtual prototyping via ESI’s VPS solver, he has successfully executed a multitude of studies. His work not only exemplifies precision and innovation but also underlines his commitment to pushing the boundaries of what is possible in engineering.

Komeil Kazemi Zarkouei – Application Engineer, Weld – ESI Group

Komeil currently works as an application engineer for Weld & Assembly at ESI, ensuring successful adoption and implementation of ESI solutions at customers. In recent years, he has developed a unique expertise on spot weld analysis covering manufacturing and performance (rupture) aspects.

Prior to joining ESI, Komeil obtained B.S. and M.S. degrees in Mechanical Engineering from IR University of Science and Technology (Iran) and a PhD in Mechanical Engineering from Carleton University (Canada). He began his post-doctoral career in 2015 in Computational Weld Mechanics with Goldak Technologies Inc. in Ottawa, Canada. After 3 years he relocated to California and began working as an Application Engineer for MSC Software in Newport Beach.

This webinar is sponsored by ESI Group.