Commercially pure copper, tool steel, and aluminum alloy among new metals on offer.

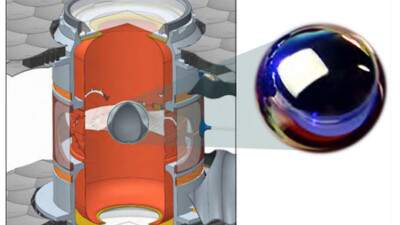

Renishaw has announced several new additions to the processable materials for its RenAM 500 series of metal AM systems. The new materials added include commercially pure copper, H13 tool steel, Hastelloy X alloy, super-duplex stainless steel and AlSi7Mg aluminum alloy. These additions are intended to provide manufacturers with the ability to create new parts for a wide range of applications.

According to the company, Renishaw is releasing these five material files for its laser powder bed fusion (L-PBF) systems after working with its customers to develop process parameters for new alloys to open up innovative applications.

Renishaw has also added new powder layer thicknesses to its current processable materials, including 90 μm titanium grade 23, 70 μm stainless steel 316L and 120 μm Inconel 718 parameters.

For the first time, the material data sheets include results of Plastometrex’s proprietary PIP (Profilometry-based Indentation Plastometry) testing. Renishaw claims that by facilitating rapid, direct testing on different sections of AM parts, this method provides a more precise and efficient evaluation of a part’s mechanical properties, in addition to complementing the company’s existing testing procedures.

“We are pleased to be adding to our portfolio of available materials to support innovative applications, and respond to the needs of our customers,” said Marc Gardon, EMEA Additive Manufacturing Applications Manager at Renishaw in a press release. “For instance, we have developed parameters for H13 tool steel, Hastelloy X alloy and super-duplex stainless steel to support customers in Spain and Portugal — SIMOLDES, ITP Aero and ADDIMEN — for applications in the tooling, aerospace and energy industries.”

The new material range opens a number of new AM applications for users of Renishaw’s RenAM 500 series:

- Pure copper, with its extremely high thermal and electrical conductivity, is well-suited to consumer electronics and heat exchanger components.

- Aluminium AlSi7Mg is a lightweight, high-strength alloy that’s well suited to various applications in the aerospace and automotive industries.

- H13 tool steel boasts excellent thermal fatigue properties and high heat resistance to provide high-temperature performance.

- Hastelloy X alloy and super-duplex stainless steel share excellent corrosion resistance and high-strength, characteristics that are well suited to the oil and gas and chemical process industries.