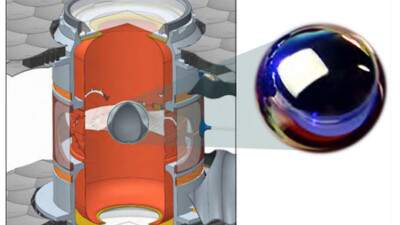

Acoustic holograms cause extremely rapid polymerization by inducing regional cavitation bubbles.

A novel method of 3D printing that uses acoustic holograms could yield an order-of-magnitude improvement in polymerization-based additive manufacturing (AM). According to researchers at Concordia University, the new approach is both quicker than existing methods and capable of making more complex objects.

The process, called holographic direct sound printing (HDSP) builds on a method introduced in 2022 that described how sonochemical reactions in microscopic cavitations regions create extremely high temperatures and pressure for trillionths of a second to harden resin into complex patterns.

Now, by embedding the technique in acoustic holograms that contain cross-sectional images of a particular design, the researchers were able to accelerate polymerization, creating objects simultaneously rather than voxel-by-voxel.

In order to retain the fidelity of the desired image, the hologram remains stationary within the printing material. The printing platform is attached to a robotic arm, which moves it based on a pre-programmed algorithm-designed pattern that will form the completed object.

Muthukumaran Packirisamy, a professor in the Department of Mechanical, Industrial and Aerospace Engineering, led the project. He believes this can improve printing speed by up to 20 times while at the same time using less energy.

“We can also change the image while the operation is under way,” he said in a press release. “We can change shapes, combine multiple motions and alter materials being printed. We can make a complicated structure by controlling the feed rate if we optimize the parameters to get the required structures.”

According to the researchers, the precise control of acoustic holograms allows it to store information of multiple images in a single hologram, enabling multiple objects to be printed at the same time at different locations within the same printing space.

For this reason, they believe that acoustic holography will be a launching pad for innovation across a number of fields: it can be used to create complex tissue structures, localized drug and cell delivery systems and advanced tissue engineering. Real-world applications include the creation of new forms of skin grafts that can enhance healing and improved drug delivery for therapies that require specific therapeutic agents at specific sites.

Moreover, since soundwaves can penetrate opaque surfaces, HSDP can be used to print inside a body or behind solid material. This can be helpful in repairing damaged organs or delicate parts located deep within complex assemblies.

The researchers believe that HDSP has the potential to be a paradigm-shifting technology, on par with the advancement light-based 3D printing technology saw with the evolution from stereolithography to digital light processing.

“You can imagine the possibilities,” Packirisamy said. “We can print behind opaque objects, behind a wall, inside a tube or inside the body. The technique that we already use and the devices that we use have already been approved for medical applications.”

The research is published in Nature Communications.