The printer marks HP’s first foray into metal additive manufacturing.

HP launched their S100 Metal Jet 3D printer at the International Manufacturing Technology Show (IMTS) in Chicago, Illinois. The company appears to be banking on the growing opportunities within the world of metal additive manufacturing.

“The natural evolution for us was going into metals,” said Ramon Pastor, Global Head and General Manager at HP, during a press briefing. “The opportunities are huge—but to realize these opportunities, several things need to happen.”

According to the company, the HP S100 printer is geared towards design flexibility and streamlined production cycles. Metal Jet allows for faster production times because—unlike laser sintering or electronic beam 3D printing—the parts are batch-printed with a crisp 1200 dots-per-inch (dpi) resolution. Furthermore, with Metal Injection Molding (MIM) powders like stainless steel 316L and 17-4PH, Inconel and even precious metals, HP claims that users can go from raw material to near-net-shape products in just one step—something that is virtually impossible with conventional manufacturing. These MIM powders are also three to five times cheaper than the powders used in laser-based and ink-based 3D printers, and are 100 percent reusable for new production cycles. That said, the HP S100 currently cannot work with reactive metals, such as titanium and aluminum.

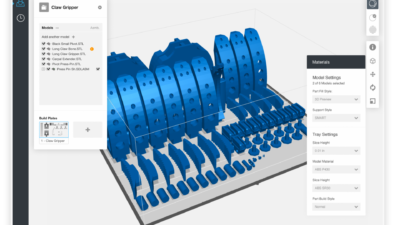

The HP S100 printer is comprised of four modular stations that facilitate continuous production cycles. It all starts with the powder management station, where the MIM powder is blended, sieved, leveled and compacted so it is ready to be transferred to the 430 x 309 x 200 mm build unit where the actual printing occurs. In the build unit, the cured powder is coated with long-chain latex polymer binding agent. The binding agent is applied layer by layer to the powder based on the geometry of the part that needs to be printed. The part assembled during this stage is called “green part” because it is not yet sturdy or dense enough for usage.

Next, the green part is transferred to the curing station where it is heat- and pressure-treated to allow the binding agent to crosslink. The green part acquires its required hardness and density. Finally, the green part is moved to the powder removal station where both the green part and excess powder can be extracted. This residual powder can be reused for new cycles. The green part is transferred to an external, third-party sintering furnace where all excess material is removed and the part acquires its final shape.

The HP S100 printer employs HP Thermal Inkjet (TIJ) print heads that can precisely deposit 630 million droplets of the binding agent during production. The latex polymer is capable of bonding with the metal so tightly that printed parts can be as heavy as 1 kg. (Compared to laser sintering, though, the HP S100 cannot produce parts heavier than this.) While parts as heavy as 5 kg have been printed in labs, the limitations are rooted in the resulting cost of production.

The HP Metal Jet S100 printer is available for installation immediately in the US, China and Western Europe.

For more of our IMTS coverage, click here.