Vartega employs a patented chemical-based process to rescue carbon fiber waste from an eternity in the landfill.

As the demand for composite materials like carbon fiber continues to grow, the manufacturing industry is faced with the possibility of surpassing production capacity. At the same time, carbon fiber waste is an alarming problem. Carbon fiber reinforced polymer (CFRP) is utilized in massive applications such as wind turbines—thousands of which are removed from service annually. The aerospace industry has an estimated scrap rate of 30 percent. Over 24,000 tons of carbon fiber waste ends up in landfills or is incinerated every year, despite being worth as much as $630 million.

It would make sense for companies to reclaim the valuable material—except that carbon fiber is notoriously difficult to recycle due to its fibers being bound by an extremely stable epoxy thermoset resin matrix. (Background: Carbon fibers are woven into fabrics and impregnated with plastic to form prepreg. This prepreg is formed into different shapes and cured into solid composite parts, which don’t melt down like steel or aluminum would.) Since carbon fiber is non-biodegradable, any waste sent to landfills will stay there forever.

Fortunately, a Colorado-based company called Vartega has patented a low-energy solvolysis process for recovering carbon fiber from high-grade, pre-impregnated scrap and dry fiber fabrics. The recycled carbon fiber—which has been found to exhibit the same mechanical properties as virgin carbon fiber—can be incorporated into intermediate materials including non-woven fabrics, thermoplastic pellets, and 3D printing filaments.

Engineering.com caught up with Vartega’s CEO, Andrew Maxey, to learn more about the technology and its applications.

Vartega’s Origin Story

Maxey’s interest in carbon fiber stemmed from his love for cycling, having worked in a bike and ski shop in Northern Michigan where he grew up. One day, when a customer had accidentally destroyed their new carbon fiber bike’s frame (by driving their car into the garage with the bike on the roof rack), a fascinated Maxey took the opportunity to cut through the frame to see what carbon fiber was all about.

A decade later, Maxey completed his mechanical engineering degree and worked in high efficiency building systems, where he learned about sustainability and green design. As his career evolved, he became exposed to textiles and recognized carbon fiber as a high value textile. When going on to oil and gas processing, Maxey thought of leveraging carbon fiber technology in the petroleum world.

“I decided to try a proof of concept in my garage with some of the background I had in textiles and oil and gas,” recounted Maxey. “I had several epic failures—just zero success for a long time—but finally stumbled upon the foundation for our chemical-based recycling process for uncured carbon fiber composites. I figured if the dots could be connected from the captive supply in the waste stream to the unmet demand for low-cost carbon fiber, that would be pretty profound.”

Maxey and three other co-founders started Vartega in 2014 as a side hustle while working in other jobs. In 2016, they raised capital, received grant funding, and proceeded to scale up their technology full-time.

Vartega’s Recycling Process

Virgin carbon fiber is expensive and energy-intensive to produce. It is traditionally sourced from crude oil, where acrylonitrile—a product of refined crude oil—is polymerized to make polyacrylonitrile fiber through heating at temperatures as high as 1000°C.

“You’ve got fossil fuels, their refining process, and all the energy into first oxidizing, then carbonizing that material,” said Maxey. “There’s a lot of embodied energy in carbon fiber. For us as an industry to put all this energy into a material and then scrap a third of it is very difficult. It’s not good for the economics or the environment.”

Unlike competitors who use methods such as pyrolysis to burn resin off of cured composites, Vartega’s recycling process is focused on dissolving the resin from uncured prepreg. Industrial solvents—the same ones that are used for manufacturing the composites—are first used to wash the prepreg. (“It’s like a carbon fiber washing machine,” explained Maxey.)

The resin solvent mixture is subsequently recovered and purified, so that secondary waste streams are not created in the process. The remaining resin-and-binder-free carbon fiber is flushed dry with carbon dioxide.

“There’s no residue,” asserted Maxey. “We don’t have a char left over on the carbon fiber, and we haven’t damaged the carbon fiber either. It’s a very gentle process so that the carbon fiber comes out a big fluffy mess. We’re patenting additional intellectual property on how to convert that into easy feed bundles. Whether it’s our recycled fiber or another feedstock or stream of carbon fiber, we’ve optimized these bundles that flow very easily into traditional plastics production. That’s an important contributing factor for how our material is easier to adopt and can be used as a drop-in replacement for traditional carbon fiber thermoplastics manufacturing.”

Once the carbon fiber is separated from its resin matrix, there’s the option of chopping and consolidating it with a compatible binder for thermoplastic compounding. Examples of final products include polypropylene and polyamide carbon fiber-reinforced thermoplastics, which are essential to the automotive industry.

Recycling carbon fiber saves 95 percent of the energy of manufacturing virgin carbon fiber—and as a result, costs 40–50 percent less. While industrial-grade carbon fiber costs $8–10 a pound, Vartega’s carbon fiber retails at $5–6 a pound.

“It becomes more accessible for industries like automotive, which historically have struggled to justify the higher price of virgin carbon fiber,” declared Maxey.

Applications of Vartega’s Recycled Carbon Fiber

Since Vartega’s recycled material retains the mechanical properties of virgin carbon fiber, it demonstrates the same strength, stiffness, thermal expansion, thermal conductivity and electrical conductivity characteristics.

“That’s important for applications where you maybe injection mold a part and can make the wall thickness of the part thinner,” said Maxey. “The material can be used in structural applications as well. We’ve demonstrated that our carbon fiber in thermoplastics has low resistivity for applications in ESD. And then thermal conductivity is actually very exciting from a heat transfer standpoint for thermally conductive electronics enclosures, for example. There’s a lot of work going into battery enclosures for the electric vehicle space. Carbon fiber also has a very low coefficient of thermal expansion, so it can be subjected to a broad range of temperatures without expanding or contracting. This is especially relevant to additive manufacturing in terms of warpage.”

Vartega’s carbon fiber is already being used in a range of commercial applications, from car parts to consumer products such as musical instruments, electronics and sporting goods. For instance, Vartega partnered with X-Hurl to design and build North America’s first carbon fiber composite hurley for the Irish game of hurling.

“Hurling sticks are traditionally made of ash wood,” described Maxey. “We were designing a composite stick to have either the same performance or improved performance over ash, and we did a whole design study with Autodesk. We looked at Moldflow and how we’d lay up the different materials, because we were looking at an extruded thermoplastic sheet. We did a foam core on the inside. We also looked at the finite element analysis to understand the flex of the hurling stick and the performance—i.e., how the ball was going to rebound, and energy transfer.”

One area with major potential for carbon fiber is the automotive industry, where vehicle lightweighting leads to increased range and fuel economy while reducing emissions. Composites are expected to play a significant role in emerging technologies such as autonomous and electric vehicles.

“The big focus for automotive is metals replacement,” said Maxey. “So, replacing steel, aluminum and magnesium to reduce weight and also consolidate parts.”

Vartega is currently wrapping up a two-year project with the Institute for Advanced Composites Manufacturing Innovation (IACMI) to address the challenges of creating consistent recycled carbon fiber-reinforced thermoplastics for use in the automotive industry. Project partners include Michelman, Ford, BASF, Oak Ridge National Laboratory, Colorado School of Mines, Michigan State University, the University of Dayton Research Laboratory, and the University of Tennessee, Knoxville. Vartega is working on characterizing and validating materials, and establishing supply chain solutions for high-volume production. Through the technical collaboration, Vartega is developing fenders and other automotive parts for Ford.

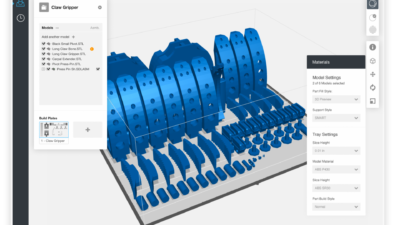

As mentioned earlier, there are considerable applications of recycled carbon fiber in the additive space. In fact, back in 2019, Vartega was awarded a National Science Foundation Small Business Innovation Research (SBIR) grant to conduct work on carbon fiber-reinforced polymer feedstocks for powder bed fusion (PBF) 3D printing, in order to produce parts that would perform similarly to injection-molded materials.

One exciting project in Vartega’s portfolio is HawkWatch, which involves raptor tracking in Northern Africa. Vartega’s recycled materials were used in the development of high-strength, lightweight solar-powered GPS transponders for the study of vultures’ migration paths.

In May 2021, Vartega launched a 3D printing filament recycling program with Braskem. Not only is Vartega’s carbon fiber-reinforced polypropylene filament being offered within Braskem’s portfolio, but customers using the filament can also send their scrap, failed prints and support material back to Vartega for recycling.

What About Supply Chain Security?

As the technology for recycling carbon fiber progresses, there are still supply chain issues to consider regarding the availability of materials. After all, if there’s no material to recycle—or no products to use recovered carbon fiber in—it doesn’t matter if the technology is advanced.

“We’re fortunate to have a very strong supply of material from carbon fiber manufacturers, aerospace manufacturers, wind energy manufacturers, as well as automotive, sporting goods and other industries,” stated Maxey. “Certain aspects of the market certainly slowed down—commercial aerospace took a big hit during COVID-19—but other areas increased and kept us on a pretty even keel. We don’t have a shortage of material to recycle, and the demand for our low-cost carbon fiber is definitely increasing. We’re doing everything we can to meet that demand, and are scaling up our business to grow and support that.”

While Vartega has a facility in Colorado for processing composite scrap, their carbon fiber recycling equipment is also designed to fit within modular units that can be deployed to companies’ production sites through Vartega’s Hardware-as-a-Service subscription platform. There is also the option of establishing regional recycling centers to handle scrap from multiple companies.

“The Pacific Northwest, Southern California, Utah, the Midwest, and the Southeast are all areas with significant carbon fiber manufacturing,” said Maxey. “It makes a lot of sense to build a distributed model that cuts down on transport and logistics—in turn, reducing the carbon footprint of the recycling process. That’s a big part of our model going forward. It’s what will allow us to scale, because that distributed supply chain also allows us to connect the supply to the demand very efficiently.”

Vartega’s Collaboration with Autodesk

In addition to the use of Autodesk’s software for the design of their equipment, facilities, production flow and parts, Vartega is supported by the Autodesk Foundation.

“We’re very aligned with Autodesk in how strongly we view impact; one of our metrics we measure and track is greenhouse gas reduction,” said Maxey. “For every ton of carbon fiber we recycle, we save 13.4 tons of CO2 versus manufacturing virgin carbon fiber. And for every ton of carbon fiber that’s then used in automotive lightweighting, we save another 47.7 tons of CO2 emissions.”

Joe Speicher, Head of Sustainability at Autodesk, weighed in on Vartega’s circularity and sustainability efforts.

“I am skeptical of the term circularity,” expressed Speicher. “It is thrown about, and it’s buzzy and ill-defined. Vartega is a perfect example to me of circularity. If they’re wildly successful, they can tackle a waterfall of waste from other industries—and we’re behind them all the way.”

To learn more about Vartega, visit their website.