Markforged presents its vision for decoupling from a crippled global supply chain via distributed factories.

Markforged has sponsored this post.

The global supply chain is a precariously balanced house of cards. Everyday, billions of dollars’ worth of goods are transported via trucks, shipping containers and cargo planes—where any hiccups are enough to bring this trillion-dollar industry to a grinding halt.

The fragility of the global supply chain is perhaps best exemplified by the marine traffic jam that is ongoing at the Los Angeles and Long Beach ports. Port operators and shipping lines are battling massive backlogs and scheduling delays that could last months. It is a costly logistical nightmare, and another blow to companies already reeling under the strain of meeting increased demand amidst a limited supply of goods during the COVID-19 era. Price hikes are anticipated for consumers. Manufacturing operations are stalled, with just-in-time delivery systems leading to idling assembly lines.

A new paradigm is essential for addressing the risks associated with conventional supply chains—and this is where the Digital Forge may offer a solution with decentralized manufacturing.

Conventional Manufacturing Versus the Digital Forge Model

Centralized manufacturing involves high capital expenditure (CapEx) upfront, and cascading risks throughout a long supply chain. Manufacturers must invest in a plant, which comprises land, machinery and tooling. Operating expenses (OpEx) follow, with the associated labor, technical expertise, raw material and energy costs amalgamating into a pile of parts. The parts are subsequently inspected, packaged and shipped—requiring further raw material, energy and labor (and let’s not forget those pesky supply chain challenges). Then comes warehousing, which involves its own land, labor and packaging requirements.

All this is to get one part in hand. Want four different parts? That is potentially four massive, separate operations. While conventional manufacturing does benefit from low unit cost, part versatility can be low and changes are often too costly to easily implement.

Supply chain risks may apply to outsourced manufacturing, too. Sure, companies would no longer need to invest in CapEx—but if there are material and labor shortages throughout the entire network, that can still be a problem.

Conversely, a platform such as the Digital Forge has the potential to invert manufacturing capital allocation and restabilize the way things are made. “By shifting the means of production away from large plants and closer to the point of need, capital is subsidized and risks are absorbed by the end users of a firm’s products,” asserted Charles Lu, application engineer at Markforged. “We’re taking the factory out of manufacturing by moving manufacturing out of the factory.”

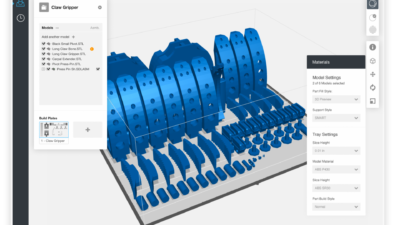

Before we unpack that, let’s review some Digital Forge basics. The Digital Forge is an ecosystem of software, materials and printers. Customers subscribe to Markforged’s software, which provides the ability to generate digital files. Materials and 3D printers are delivered to various endpoints. (While that does involve shipping, it is more of a one-time thing versus when millions of items regularly need to be packaged, shipped and warehoused.) The outcome of each “miniature factory” is a part on site directly when it is needed, reducing external dependencies associated with the global supply chain.

“We’re talking about a huge reduction in CapEx, which you may not even pay for as a manufacturer,” said Lu. “It may be subsidized by the customer, along with OpEx. The customer can get a box on site and create a wide variety of outputs through a versatile manufacturing process that is not reliant on specialized tooling or machinery. 3D printing can make many unique part types that, conventionally, would require multiple supply chains to fulfill. Instead of investing in minimum order quantities of thousands of parts and waiting weeks or months for an operation to complete, the risk is front-loaded into the machine and materials.”

Along with the prospect of offsetting capital and mitigating risk, this approach slashes startup and shipping lead times, and warehousing for inventory. Physical inertia is eliminated when product changes can be made digitally. While physical parts entail a lengthy manufacturing process, digital fabrication deals primarily with the information contained in parts—physically manifesting as 3D-printed parts at the point of need. Greater visibility is granted into the supply chain when it is at home.

“The variety of items needed to be kept in inventory is also drastically reduced, as different parts can be made using the same raw material,” added Lu. “A business which once ran a warehouse for specialty Delrin spacers, rollers and pads, for example, could reduce their physical inventory from thousands of individual SKUs to a half-dozen filament SKUs. A printer could use those filaments to produce any part in a digital catalog.”

Vestas, the world’s largest manufacturer of wind turbines, is one company that uses the Digital Forge for the fulfillment of its inventory. Markforged’s partner reseller, Wurth Industrial, provides a Digital Kanban solution to companies like Vestas that have a need for critical tooling and spare parts. Whenever a printable part is taken from smart bins, a signal is sent to the Digital Kanban, which in turn sends a signal to an on-site Markforged printer to automatically generate a replacement. With the digitized inventory and automated re-ordering system in place, Vestas can distribute tools directly at endpoints such as print farms or offshore turbines without the need for shipping, warehousing and packaging logistics.

“It allows them to reduce risk and increase supply for just the cost of the machine,” Lu stated.

A company that specializes in designing for applications may want to formulate their own materials to optimize the performance of their parts. Instead of developing their own printing equipment in-house, managing production and subsequent inventory, they can focus on their speciality in part design and materials, leaving the rest to the platform.

“As Markforged grows, we may continue to incorporate validated third parties to provide software integrations, services, part files, hardware and materials,” conjectured Lu. “It is possible that in the future, a company could connect their own hardware to the platform, or validate their materials for use on Markforged systems or even their own systems.”

“It may be possible for Markforged customers to make subsets of their part catalogs accessible on the Digital Forge platform to other Markforged customers,” continued Lu. “These customers may one day be able to license parts or pay for individual prints, instead of going through a conventional supply chain.”

Why Hasn’t 3D Printing Democratized Manufacturing Yet?

3D printing has been promising to make manufacturing accessible for over a decade—but up until this point, it hasn’t really happened. According to Lu, this is because manufacturing is inertial and difficult to change.

“Quality control takes time, setting up a factory takes time and changing processes takes time,” said Lu. “The learning curve has also been an issue; not everybody knows CAD, and not everybody knows how to operate and maintain printers.”

Another factor has been limited materials and machine capabilities. Quality control has been an issue in terms of printer-to-printer consistency, with further variations being observed when using different materials or software.

“At the time when 3D printing was getting popularized, there was no cloud,” added Lu. “Consumer 3D printing came before widespread adoption of cloud computing, so print tuning was done at the printer level rather than at the fleet level. Software versions were not standardized, and files were hosted in disparate locations, with IP not respected or enforceable. File quality is not controlled for online repositories like Thingiverse.”

The Digital Forge Approach

When it comes to the steep learning curve, Lu believes the initial approach has been short-sighted. “Early consumer 3D printing was fixated on the needs of consumers,” he said. “We believe problem-solving in the digital age begins with engineers who are already trained to use CAD and wield machines. Rather than starting at the end trinket and saying you can print anything, we are starting where it makes sense and working backwards from there.”

Markforged leverages the cloud for integrating online repositories, whether it’s for software services, part models, or analytics. “Rather than asking tens of thousands of users to manually install a plugin for each repository, or pushing software updates each time we enable a new integration, we have the ability to build connections with friendly platforms and make those available immediately in the browser,” shared Lu.

When working with digital parts rather than physical ones, digital rights management is a key consideration. “There is virtually nothing protecting a designer’s intellectual property once it has been downloaded,” conveyed Lu. “When designers and users agree to work on a trusted platform, the platform acts as a broker, protecting the designer from piracy and the user from risk.”

One major focus area for the Digital Forge platform is its material capabilities. Industrial-grade metal and strong composites ensure that machines build engineering-quality tools.

Rather than going through numerous iterations of hardware development, Lu says Markforged’s 3D printers are designed to be future-proof in order to leave more room for innovation in the software realm.

“A printer today off the line could hit your +/- 0.002” tolerances,” he explained. “How do you know that will be the case six months after it’s been used? Or after it’s been moved from one plant floor to another? What about after routine maintenance, or mishandling by an operator? Smart software and prescient hardware decisions have allowed us to keep improving. Having the ability to inspect and validate has come along with thinking about software and hardware together.”

As opposed to conventional manufacturing workflows where additional labor and equipment is required for the inspection stage, Markforged’s printers come with integrated inspection features. For example, Blacksmith in-process laser inspection serves to eliminate printer-to-printer variation, ensuring quality control within a distributed platform.

“Blacksmith not only helps calibrate a machine so that every machine is outputting the same thing, but scans parts to confirm if they are good or not, and produces automated reporting,” said Lu. “The Digital Forge is the only platform that allows manufacturers to verify the outcomes of different printers, and ensures uniformity across a fleet of printers. Rather than a technician doing calibration checks during installation and routine service on site, we have deferred that to a laser on the machine—making the maintenance and need for service a responsibility of the software, so that it becomes a lot easier to keep machines in check.”

Markforged’s Eiger Fleet allows manufacturers to implement this more broadly at scale. The software manages files across a fleet of machines that are distributed to different endpoints, ensuring standardization throughout one unified platform. Along with role-based access controls that dramatically reduce the steps for adding users, the Eiger Fleet enables the tracking of print job completion rates, print success rate and more. The transparency of printer utilization across the fleet in turn helps with decision-making in terms of where more printers may be needed.

“Owning the Digital Forge ecosystem means that we are held accountable to our customers’ standards,” said Lu. “When things go wrong, we know where to look because we have data spanning the process. Much like numeric control and industrial automation improved quality and reduced risk by taking human error out of manufacturing, the Digital Forge reduces risks associated with the organization of information, human processes and economics by building those into the machinery.”

To learn more about the Digital Forge, visit Markforged.