The two companies developed the technology by combining sub-micron resolution printing and bioprinting technologies.

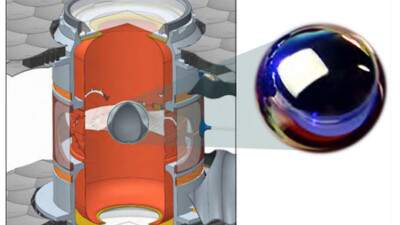

3D printing solutions developers CELLINK and Nanoscribe have unveiled their all-new Quantum X bio 3D printer. This is the latest variation under Nanoscribe’s Quantum X 3D printer platform that can print objects in nanometers with a minimum feature size of 100 nm (0.0001 mm). The new Quantum X bio features sub-micron resolution printing capabilities that will enable miniaturized bioprinting. According to the two companies, the 3D printer system was specially developed for research institutions and research and development teams that want to use advanced biomedical applications such as tissue engineering and regenerative medicine.

The Quantum X bio operates on a custom version of Nanoscribe’s Two-Photon Polymerization (2PP) technology with adaptations for bioprinting applications. Thanks to CELLINK’s bioprinting expertise, the two companies were able to add various features, including precise temperature control, a sterile environment, as well as compatibility with functionalized biomaterials. Nanoscribe achieved this by using its 2GL 3D printing process. The printer’s ability to deliver detail in biofabrication is already anticipated to enable increased innovation in different industries, including smart hydrogel materials, drug delivery, mechanobiology, and vascularized tissues.

The Quantum X platform was first introduced back in September 2021 and was adapted from the more popular two-photo resin 3D printing approach, which allows very tiny structures to be created within a vat of photopolymer resin. It can provide a high level of resolution in a 50 x 50 mm build chamber, which lets the machine print various types of microscopic objects. The collaboration with bioprinting company CELLINK has transformed the platform into a bio printer.

“Based on Nanoscribe’s engineering excellence, the proprietary additive manufacturing technology is customized and reimagined in collaboration with the expertise of bioprinting experts at CELLINK. Transferring Nanoscribe’s submicrometer resolution to biofabrication is the key to effectively accelerating innovation across life science applications.”

Both companies are under bioconvergence firm BICO, which designs and develops technologies for bioprinting, multiomics, and cell line development and diagnostics. According to the company, the next generation of health care solutions will actively incorporate biological systems and processes with the lines between biology, engineering, nanotech and IT becoming increasingly blurred.

“Our industry-proven Two-Photon Polymerization technology, combined with CELLINK’s bioprinting expertise, will be a game changer for many challenging biological and biomedical applications, and we look forward to expanding our market leading 3D Microfabrication position in the life sciences with a dedicated bioprinter,” shared Nanoscribe CEO Martin Hermatschweiler. “The launch of Quantum X bio confirms the power of collaboration within the BICO Group and we are excited to unlock the full potential at the merger of technical and life science disciplines.”

According to BICO, the new 3D bioprinter will enable manufacturers to fabricate custom scaffolds for cell studies, microfluidic elements, microneedle arrays, as well as microrobots. The company rebranded back in August 2021 and has already been issued two new patents for the 3D bioprinting of temperature-sensitive bioinks. These will enable higher cell viability and enhance reproducibility with different bioinks such as collagen and gelatin. Nanoscribe was acquired by BICO in May 2021 for 50 million euros under CELLINK, which allowed the company to integrate 2PP technology into its systems to enable the fabrication of lifelike soft tissues.

For more information, visit Nanoscribe’s website.