This Week in Engineering explores the latest in engineering from academia, government and industry.

Episode Summary:

With the race to replace internal combustion engines with electric vehicles heating up, the question of where this new production will come from is the pressing issue for the industry. Will it be new facilities or the conversion of existing plants? Ford appears to be doing both, with a major conversion of the existing facilities and the announcement of two very large new operations, an assembly plant in Tennessee and a joint venture with SK Innovation for battery production in Kentucky.

Sustained hypersonic flight has been a hot topic of research in aerospace for decades, and hot on the heels of recent Chinese advancements in scramjet technology, Raytheon and Northrop Grumman have announced the successful test of an air breathing hypersonic missile built for the Defence Advanced Research Projects Agency. While current scramjet technology is suitable only for short duration use in weapons, similar technologies are under development that could be scaled to allow true single-stage to orbit performance with hybrid engines.

Access all episodes of This Week in Engineering on engineering.com TV along with all of our other series.

Transcript of this week’s show:

To see any graphs, charts, graphics, images, and/or videos to which the transcript may be referring, watch the above video.

Segment 1: Ford Motor Company has announced the company’s biggest investment yet in electric vehicles. Ford CEO Jim Farley has announced an $11.4 billion investment in electric vehicle and EV battery technology, including a mega campus in Tennessee and two battery plants in Kentucky. 11,000 jobs will be created by the two projects.

The Tennessee operation will be called Blue Oval City, built on a 6 mi.² site and will assemble next-generation electric F-series light trucks as well as batteries. The large project will employ approximately 6000 and will be both carbon neutral and zero waste to landfill. The campus will treat wastewater on site and Ford hopes to eventually operate with zero net water draw from local sources. The campus will also include facilities for key Tier One suppliers who will be cloud connected to the Ford operations.

The other project will be called the Blue Oval SK Battery Park, two battery plants built by a joint venture with Korean battery maker SK Innovation, which will build batteries for multiple Ford and Lincoln EV models. About 5000 workers will be employed in the 1500-acre Glendale, Kentucky operation which will produce 86 GW hours of battery capacity annually.

Scheduled to open in 2025, the location was chosen for easy delivery to Ford’s North American assembly plants. Why so much investment so soon? The company expects that approximately half of Ford production will be all electric by 2030.

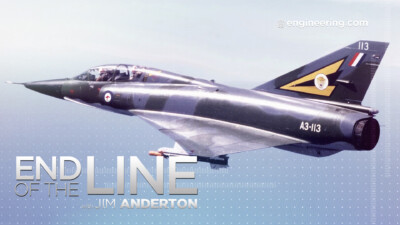

Segment 2: The race for higher speeds in aviation has been ongoing since the earliest days of wood and fabric biplanes. Development of jet engines and rockets has always been about speed, but for jet engine technology, hypersonic speeds, approximately Mach 5, have been difficult to achieve. This flight regime operates beyond the capability of engines with rotating elements and uses an exotic variant of ramjet technology called scramjets, or supersonic combustion ramjets.

The concept is to manage shockwaves in the engine’s intake and use them to compress that air, inject fuel and ignite the mixture to produce thrust. There are multiple challenges, notably airframe heating, but in an important development, Raytheon and Northrop Grumman have announced the successful flight test of a scramjet powered hypersonic air breathing weapon concept, or HAWC, in a test for the Defense Advanced Research Projects Agency and the U.S. Air Force.

The test article was carried under the wing of the mother aircraft, then launched with a solid fuel rocket to bring it to supersonic speed, where the scramjet took over. Sustained hypersonic flight with air breathing engines is a breakthrough, and for missile applications, hypersonic weapons are predicted to be a key enabling technology for new generations of lower cost, long-range missiles.

The Raytheon/Northrop Grumman program is aimed at delivering a prototype for the US Department of Defense, with no single service announced as primary users of the technology at this stage of development. Other nations are actively working on the technology, notably China. The Beijing-based Institute of Mechanics has reported a testbed hypersonic engine capable of operating for 10 minutes, which is expected to be the basis for a new generation of Chinese military missiles.

The relatively short run times of military hypersonic airframes make hypersonics achievable with current technology, but the UK-based Reaction Engines is developing advanced hybrid technology which, if successful could deliver that Holy Grail of astronauts: single-stage to orbit.

We’re long way from that achievement, but the Chinese and US military scramjet programs will likely feed valuable technology and material science into future civilian programs, exactly the way the commercial jet transport industry evolved. Faster is better.