On the verge of failure, the company abandoned its original mission and reconfigured its product to fill a profitable niche.

For several years, the buzz around privately-funded spaceflight has been dominated by Musk’s photogenic falcon 9 boosters and Jeff Bezos’ less-photogenic cowboy hat. But for those in the know, many exciting things are happening in the industry beyond SpaceX and Blue Origin.

Stratolaunch is one such company, based in the Mojave desert and specializing in high-speed test flight and air-launch capabilities.

But that wasn’t always the mission. Stratolaunch was founded 2011 by Microsoft’s Paul Allen and SpaceShipOne’s Burt Rutan with the goal of furthering air-launch as a space transportation option. As the company developed the three components of their system—the carrier aircraft, the launch vehicle and the mating system—progress was disrupted by the death of Paul Allen in 2018. Following his death, the company announced in 2019 a halt of development of launch vehicles and that the company would be sold. Stratolaunch was widely deemed a failure. However, following the successful change in ownership, it has surged back, growing to over 360 employees.

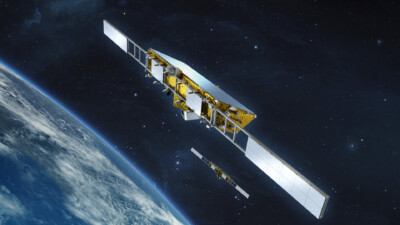

The company has announced several successful missions involving the iconic Roc carrier aircraft, developed in collaboration with Scaled Composites as part of Allen and Rutan’s original vision for the company. The most recent mission achieved the first successful test flight of the Talon-A launch vehicle. According to the press release, primary objectives for the flight test included safe air-launch release of the TA-1 vehicle, engine ignition, acceleration, sustained climb in altitude and a controlled water landing.

The “Roc” plane

Codenamed after a mythical bird of prey that carried away elephants and rescued sailors lost at sea, the Roc is one of the world’s largest airplanes and is a feat of aerospace engineering. With a wingspan of 385 feet (longer than a football field) and a take-off weight of 1.3 million pounds (589,670 kg) the plane boasts six Pratt & Whitney turbofan engines and a unique twin-fuselage design, allowing vehicles to be launched from the centerline instead of against the fuselage as in other air-launch systems, which improves safety.

The Roc has a payload capacity of 500,000 lbs (226,796 kg). During the 2019 maiden flight of the Roc, it reached an altitude of 17,000 feet and a top speed of 189 mph (5181.6m at 304 km/h.)

During the recent first powered flight of the TA-1 craft, the Roc carried the TA-1 to an altitude of 35,000 feet (10,668 meters), where the TA-1 released, approaching speeds of Mach 5. The specific altitudes and speeds of the TA-1 during the test are secret.

What is Air-launch?

While most people are familiar with vertical launch of spacecraft, Air-launch is the concept of high-altitude launch of an upper-stage spacecraft from specially modified carrier aircraft. The famous Bell X-1 aircraft, the first vehicle to break the sound barrier, launched from a B-29 aircraft. Similarly, the North American X-15 rocket vehicle launched from a B-52. While the low cost of the SpaceX Falcon 9 system is proving difficult to compete with for launch of most payloads today, the technology remains an exciting alternative with many notable advantages.

According to a paper published by Rebecca Mitchell at the University of Colorado Boulder , the method’s numerous advantages include:

Less fuel: This is probably the most obvious benefit. Simply put, the air-launched vehicle catches a ride to the thin upper atmosphere, reducing fuel required to achieve orbit. In addition, the release angle can further reduce fuel mass. According to Mitchell, an air-launched vehicle requires a fuel mass equal to it’s empty weight, while a vertically launched vehicle with a propellant mass fraction of 0.63 has to carry propellant equal to twice its empty weight.

Launch site location: while the azimuth of a vertical launch is constrained by the launch site latitude or higher, the carrier aircraft can be flown to any latitude before launch. This opens up a greater variety of orbits, including equatorial orbits. This capability reduces costs for certain orbits compared to vertical launch and makes rendezvous orbits easier to achieve.

Doesn’t make a mess: non-reusable vertical launch vehicles need to be launched over water or desert, but air launch systems are reusable and launches take place at high altitude.

Reduced Delta-v (Δv): horizontal launch vehicles accelerate horizontally and then must pitch vertically, but air launch vehicles can be released at a pitched angle.

No launch pad infrastructure: on the ground, an air launch requires a runway, while a vertical launch pad may require towers, sound suppression systems and more.

Quieter launches: at high altitude, the sound of the rocket does not reflect off the ground and the thinner atmosphere carries less sound.

Better security: a vertical launch facility is a publicized and vulnerable location, making covert or secure launches more difficult. A launch pad is also vulnerable to attack or damage, while air launch systems can use any runway.

Weather-agnostic: air launch systems can fly around or over bad weather, making launch schedules more reliable.

Quick access to space: emergency or short-notice launches are possible with air-launch systems as they avoid some of the complex launch preparations of vertical launch systems.

According to Mitchell, Air-launch also has some major disadvantages which have significantly hampered adoption of the technology in commercial spaceflight. including:

- Carrier aircraft can be complicated and expensive (Stratolaunch’s flagship carrier plane, the Roc, is by some measures the world’s biggest airplane).

- Spacecraft size is limited by payload capacity of the carrier vehicle. (Stratolaunch Talon-A craft is 8.5m long. For comparison, Dragon, the SpaceX cargo- and passenger-carrying craft, is 8.1m long.)

- Separation of the spacecraft from the carrier can be dangerous.

- Propellant boil-off has been a problem for some systems during the climb.

Shifting Focus

During the company’s sale and transition of leadership in 2019, many critics deemed Stratolaunch a failure. The company’s mission to bring air-launch into the spaceflight industry as a viable alternative to vertical launch efforts such as SpaceX and Blue Origin faltered. Allen’s original 2011 vision included air launch of rockets carrying cargo, astronauts and tourists. With Allen’s death, the company lost a major source of funding that may have allowed Stratolaunch to compete with the economical SpaceX Falcon 9 system for lucrative satellite launch contracts.

However, Stratolaunch has found success by going after the hypersonic research and development niche rather than by pursuing space launch projects. Over the past year, the company has made significant progress toward full-scale availability of the Talon-A craft as a test platform:

Hypersonic Test Flight Applications

The company’s shift to hypersonic test flights has a specific set of applications. Defined by the company as access to “a wind tunnel in the sky,” the goal of the Talon-A craft, launched by the Roc airplane, is to carry customer payloads into the hypersonic environment. As an autonomous vehicle, the Talon-A is programmed to deliver specific flight profiles, collecting data about how payloads perform under these conditions.

According to a recent article in Defense News, Stratolaunch CEO Krevor stated that the system costs an order of magnitude less than the average U.S. Department of Defense hypersonic flight test, which costs approximately $100 million. Krevor said that with a planned 1-month flight cadence, Stratolaunch could provide ROI back to the DoD by the end of 2024 or early 2025.