Brilliant design meant that Saturn 1 launch vehicles flew for 15 years with no failures.

The Saturn 1 project originated with a U.S. Army requirement for a heavy lift launch vehicle in the late 1950s and was ready for initial test flights shortly after President Kennedy announced the Apollo moon landing program.

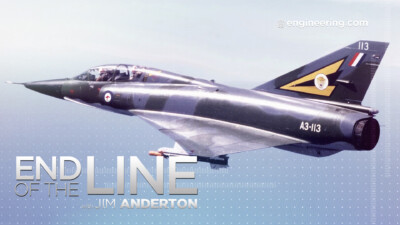

Access all episodes of End of the Line on Engineering TV along with all of our other series.

* * *

Episode Transcript:

Designing, building and flying large space launch vehicles is damned hard. Ask Elon Musk.

Missiles into space have only been a thing for 65 years, but throughout that time, the quest has always been about bigger, more powerful and more capable launch vehicles. The first satellite, Sputnik 1, was the size of a beach ball. Today’s communications satellites are the size of a school bus. But from the beginning, the desire to lift larger, heavier payloads has been there, and along with that has been pressure on engineers to design for performance and reliability at the edge of available technology.

Over at SpaceX, the design philosophy is to build fast, break often, and iterate to success. That is a faster path forward, but an expensive one. NASA tends to go on the other direction, with a design, test and retest philosophy that can consume the better part of a decade and several billion dollars to get a flight article onto a launch pad.

But take a look at this engineering masterpiece: this is a Saturn 1. This project originated with a U.S. Army requirement for a heavy lift launch vehicle, a project which was then transferred to the newly formed NASA and was ready for initial test flights shortly after President Kennedy announced the Apollo moon landing program.

The timing was perfect, since the program needed launch vehicles to test Apollo flight hardware. Reliability of launch vehicle systems early 1960s was not good. Pad explosions, guidance problems, propulsion failures, all were surprisingly common, but this vehicle in its first iteration, flew 10 times between 1961 and 1965, with no failures.

The follow-on vehicle, Saturn 1B, flew nine times between 1966 and 1975, including four manned flights for the Apollo and Skylab programs, again with a perfect record. That’s 19 launches without a failure. So how they do it? From an engineering management perspective, NASA’s George C. Marshal Space Flight Center managed the program with the first stage built by Chrysler, and the ultimate second stage by Douglas.

The final version of the second stage formed the third stage of the Saturn 5 moon rocket, but what launched the program to success was the first stage. And what made it incredibly reliable was brilliant design. Instead of the time-consuming and difficult task of building lightweight monocoque tank structures with bulkheads, Saturn 1 used a cluster of small-diameter tanks attached to a spiderlike upper and lower frame.

This was brilliant for two reasons: the tanks themselves were elongated versions of designs that already existed for Jupiter and Redstone missiles, so materials, manufacturing methods and stresses were already well-characterized. Passing the loads through the spiderlike end structures simplified load path calculation and allowed for easy mounting of the eight Rocketdyne engines.

Disadvantages? This design was heavy, and relatively expensive to build in series production. But the program it was designed to serve was not a commercial launch service, and the very mission statement that drove Apollo meant trading money for speed. And in the end, the Saturn 1 series delivered a perfect flight record, and four crews delivered safely to low Earth orbit.

Most engineering in transportation is about arranging and rearranging existing parts, subassemblies and assemblies into new and useful things. In this case, a critical factor was an early program start, earlier in fact than any actual demand for heavy lift launch capability. Apollo came later, and Saturn was already in place. A safe, reliable system, already in place when needed.

How many government operations today can say they delivered that?