The 2023 State of Smart Manufacturing Report from Rockwell Automation says quality was the top response in several categories.

The demand for continuously improving quality is creating the need to accelerate digital transformation according to 45 percent of respondents, says Rockwell Automation’s latest report on smart manufacturing.

The 8th annual edition of the State of Smart Manufacturing Report from Rockwell Automation, conducted in association with Sapio Research, surveyed more than 1,350 manufacturers across 13 of the leading manufacturing countries.

Quality is Driving Digitalization

This prioritization across the responses from global manufacturers demonstrates how the industry plans to foster growth despite disrupted supply chains and new regulations, while maintaining agility and top-quality products.

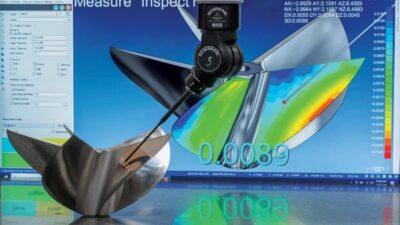

The report says quality was the top accelerant for digital transformation, with minimizing costs coming in second. Quality was also considered the number one area affected by artificial intelligence in manufacturing, with automation following closely in second place. Lastly, improved quality was the number one outcome expected from smart manufacturing adoption, while reducing costs was runner-up.

The report also says quality management systems (QMS) are the smart manufacturing systems that have seen the largest ROI, followed by manufacturing execution systems (MES) and enterprise resource planning (ERP).

Product quality or safety was selected as the most important element in environmental, social and governance (ESG) and sustainability programs, followed by reducing manufacturing waste and recycling. All of the responses revealed the growing attention on the “circular economy,” which is based on eliminating waste and pollution by designing products and processes to maximize efficiencies and extend product life with a particular focus on repair and reuse.

“Manufacturers are continuing to seek opportunities for profitable growth but are realizing that uncertainty in workforce availability is impacting quality, along with their ability to meet evolving customer needs,” said Veena Lakkundi, senior vice-president of Strategy and Corporate Development for Rockwell Automation. “The survey found that smart manufacturing technology is enabling manufacturers of all sizes to optimize more resilient, agile, and sustainable solutions that accelerate transformation. If we’ve learned anything from history, it’s that organizations that invest in innovation, with a bias for action, during times of uncertainty can outpace competitors.”

When it comes to the percentage of operating budget invested in technology, India leads the way at 34.71 percent, followed by the U.S. at 26.96 percent, and Japan at 24.23 percent. Europe was well below the global average, investing only 21.6 percent of operation budgets towards technology.

“Manufacturers expect to mitigate risk through interoperable technology, tighter processes, and connected people to build resiliency and drive future successes,” said Sachin Mathur, director of software and control, EMEA at Rockwell Automation.