Inspection software adds global registration, advanced RPS alignment and additional sensor support.

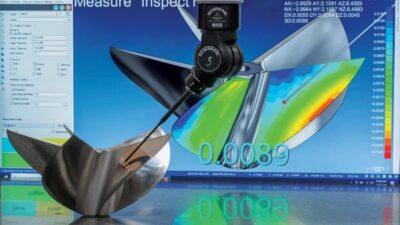

The latest version of Verisurf’s measurement software, Verisurf 2024, will be on display at the company’s booth in the upcoming Control show in Stuttgart, Germany. Designed for automated quality inspection, reporting, scanning, reverse engineering, tool building and assembly guidance, the software is built on a 3D CAD/CAM platform using model-based definition (MBD).

“Verisurf software is under constant development,” said Nick Merrell, EVP of Verisurf Software, in a statement from the company. “We work with customers every day to solve measurement challenges with practical solutions. These enhancements are delivered to customers throughout the year as software updates and are also included as part of our annual version release.”

The latest version of Verisurf includes several programming and productivity features that aim to improve metrology workflows via automation in addition to maintaining repeatable process control.

The company highlighted three new features for Verisurf 2024 in a recent press release.

- Global Register: Designed to align scan data to nominal references for manual or automated inspection plans, the company claims this feature will improve registrations between datasets, including cloud-to-cloud, cloud-to-mesh, mesh-to-mesh and cloud-and-mesh-to-CAD.

- Advanced Reference Point System (RPS) Alignment: Driven by alignment requirements in the automotive industry, this feature is intended to simplify the RPS process by using workpiece points, features, constructs and surface points to lock in alignment with a CAD model. This also includes greater control of orientation, rotation, position, weight and target type.

- Renishaw REVO Sensor Support: Verisurf 2024 will support two more REVO sensors—Renishaw’s Ultrasonic Probe (RUP1) and Surface Finish Probe (SFP2). The RUP1 evaluates the thickness of typical metal parts ranging from 1mm to 20mm with an accuracy of .010mm, while the SFP2 evaluates surface finish/roughness on a variety of surfaces, including bores as small as 5mm.

According to the company, the software is compatible with all CAD file formats, and the Verisurf Device Interface (VDI) communicates with and operates all programmable and portable CMMs for universal CMM programming and inspection compatibility.

Control attendees can visit the Verisurf booth for various demonstrations of the new software, including robotic 3D scanning, 5-axis CMM programming, and automotive body panel inspection, among others.