This white paper will address various environmental initiatives and technology changes and their impact on the chemical processing, water treatment, metals finishing, and rubbers and plastics processing industries.

As industrial processing companies worldwide struggle to regain their footing in the aftermath of the COVID pandemic, while battling labor shortages and ongoing supply chain disruptions, they’re watching two global trends: more robust sustainability initiatives and increased use of digitalization.

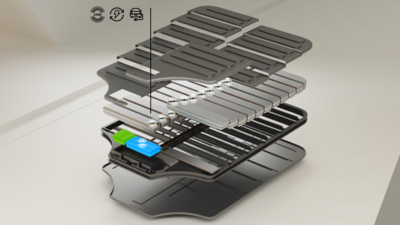

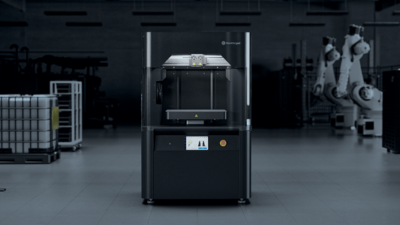

In terms of material technologies, manufacturers are looking to power up their capabilities in 3D printing, alternative raw materials, biotechnologies, materials science, and battery management. Skills that will be in high demand within these areas include computer-aided design, additive manufacturing, bioanalysis, computational biology, as well as specialized expertise in plastics technology, liquid crystal, nanomaterials, and other skills related to material technologies, according to an article in hrforecast.com.

Artificial intelligence, IoT and robotics are just a few examples of applications that can be used to track the processing phases of materials, identify resource waste and optimize raw materials consumption. With the right use of digitalization, the CO2 reduction targets set by governments will suddenly no longer seem impossible, according to an article in Rubber World.

This white paper will address various environmental initiatives and technology changes and their impact on the chemical processing, water treatment, metals finishing, and rubbers and plastics processing industries.

Your download is sponsored by Parker Hannifin.